OUR MISSION

Etorch Pharmtech Co., Ltd offers high-quality solutions for Vial Filling Lines, Ampoule Filling Lines, Infusion Lines, Syrup Production Lines, and Pharmaceutical Liquid Filling Lines. Our advanced Water Treatment Systems and Packaging Solutions ensure an optimal cost-benefit ratio, tailored to meet the exact needs of our customers' production requirements. We are committed to delivering world-class technical service, forging strong and lasting relationships with our clients.

OUR VALUES

Commitment ·

Trust ·

Team Work ·

Effective Communication ·

Honesty ·

Service Attitude ·

Positivity ·

Proactivity ·

WE BOOST YOUR PROJECT WITH

QUALITY

At ETORCH Group, we are committed to delivering the highest quality in all aspects of our solutions, including Liquid Filling Lines, Water Treatment Systems, and Packaging Equipment. We implement continuous improvement programs and standardize production policies to ensure our equipment meets the most stringent quality standards, providing our customers with reliable and efficient solutions.

CUSTOMIZATION

Our machines are designed to meet your exact process requirements, adhering to User Requirement Specifications (URS), Good Manufacturing Practices (GMP), and all applicable regulatory standards. Whether you need a tailored Filling Line, or any other specialized equipment, we ensure it aligns perfectly with your operational needs.

DOCUMENTATION

We provide complete equipment validation documentation, including DQ, DS, FS, HDS, SDS, IQ, OQ, PQ, FAT and SAT in the languages you require. This comprehensive validation documentation supports seamless integration and compliance of local pharmaceutical GMP requirements of your product.

24/7 SERVICE

Our highly qualified engineers offer 24/7 technical support to ensure our sold machines' continuous operation and minimize downtime. Our dedicated support team is always available to assist you.

35

Customers located in 35 countries

15

More than 15 years of expertise

2,500

More than 2,500 machines sold

HOT PRODUCTS

HOT PRODUCTS

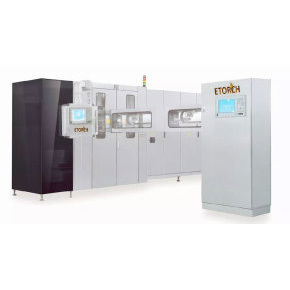

The JKFFL series vial washing-sterilization-filling-stoppering linkage line includes the JKQX series vertical ultrasonic washing machine, JKRX series hot air circulation sterilization tunnel, JKFF series filling and stoppering machine and JKZ capping machine. The model can be configured as a complete line or used as separate machines. It performs water spray filling, ultrasonic cleaning and water rinsing (internal and external), compressed air flushing (internal and external), preheating, drying and sterilizing to remove pyrogen, cooling, filling, stoppering, capping, and other processes. This line accommodates vials ranging from 2-30ml and meets the requirements for washing, drying, pyrogen removal, filling, and sealing throughout the production process.

Learn More >>Pure water equipment requirements:The water quality meets all the provisions of China pharmacopoeia standard and FDA; Automatic equipment operation and conditional automatic processing program (such as back flush, regeneration, acid-washing and disinfection procedures); Monomer and pipe equipment meet GMP requirements (all such back end processing equipments as sterilizer, membrane filtration, terminal water tank and pipeline adopt the 316L material and the pre-treatment pipeline adopts SUS304 material).

Learn More >>Multi-effect Water Distiller System

S series multi-effect water distiller is designed according to theprinciple of falling film and multiple-stage evaporation. The firsteffect is to conduct heating by external heat source (industrial steam)and then each pillar can get enough heat energy by using the purevapor produced from the fore-effect. The material water that did notevaporated in the first effect can be taken as the material in the nexteffect and so on.

Learn More >>Light inspection and leakage detection machine

The inspection machine is designed for detecting leaks and inspecting vials, ampoules, lyophilized products, soft bags, and BFS ampoules.

Learn More >>DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP160F is a blister machine in the intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

Learn More >>The JKAFL series ampoule washing-sterilization-filling-sealing linkage line combines the JKQX series vertical ultrasonic washing machine, JKRX series hot air circulation sterilization tunnel, and JKAF series filling and sealing machine. This model can operate as an integrated line or as individual machines, providing flexibility for different production needs. The line carries out a series of processes, including water spray filling, ultrasonic cleaning and rinsing (internal and external), compressed air flushing (internal and external), preheating, drying and sterilization to remove pyrogens, cooling, nitrogen flushing before and after filling, preheating for sealing, and secure sealing. This production line supports ampoules ranging from 1ml to 20ml, ensuring that all requirements for washing, sterilizing, pyrogen removal, filling, and sealing are met with high precision and efficiency. It is suitable for various pharmaceutical production environments, ensuring consistent quality and compliance with industry standards.

Learn More >>BFS Blowing Filling Sealing Machine

The Blowing-Filling-Sealing (BFS) Machine is an innovative aseptic packaging technology designed to optimize the production process for pharmaceutical-grade liquid products. This system ensures the extrusion of pharmaceutical-grade PP/PE particles into containers, followed by automatic filling and sealing under strictly aseptic conditions. By minimizing human interaction and environmental exposure, the BFS technology effectively reduces the risk of contamination, making it an ideal solution for sterile liquid preparation in various applications.

Learn More >>Non-PVC Film Soft Bag Filling Line

The Non-PVC Film Soft Bag Filling Line by Etorch is engineered using advanced international technology to meet the needs of both domestic and international markets. This line utilizes non-PVC multi-layer co-extruded film bags for infusion solutions, which are characterized by their non-toxic nature, excellent liquid compatibility, water barrier properties, and long shelf life. Capable of withstanding high temperatures of 121°C for sterilization and resistant to low temperatures, these bags are easy to transport and recycle, making them an environmentally friendly choice in soft bag infusion production.

Learn More >>The Infusion Bottle Filling Line is a comprehensive system designed for high efficiency in the pharmaceutical manufacturing process. It comprises key components: the JKGP Turntable, JKQCX Rotary Cylinder Ultrasonic Washing Machine, JKRX Sterilizing Tunnel, JKGS Filling and Stoppering Machine, JKZ Star Wheel Positioning Capping Machine, and JKLT Vertical Adhesive Labeling Machine. This versatile line is engineered to handle bottle sizes ranging from 20 to 500 ml, offering capabilities for feeding, washing, drying, sterilizing, filling, stoppering, crimping (screwing), and labeling. By simply changing the mold specifications, the line can accommodate various product types, making it suitable for diverse applications in the pharmaceutical industry while ensuring easy adjustments for different production requirements.

Learn More >>Glass Bottle Syrup Filling Line

The Glass Bottle Syrup Filling Line is an advanced system customized for efficient pharmaceutical syrup production. This line consists of several key components: the JKGP Turntable, JKQCX Rotary Cylinder Ultrasonic Washing Machine, JKRX Hot Air Circulating and Sterilizing Tunnel, JKGT Filling and Screw (Crimp) Capping Machine, and JKLT Vertical Adhesive Labeling Machine. It is designed for the handling of 20-500 ml round glass bottles, facilitating operations such as feeding, washing, drying, sterilizing, filling, capping, and labeling. The modular design allows for easy adjustments to accommodate various product sizes by simply changing the mold specifications, making it suitable for a wide range of applications in the pharmaceutical sector.

Learn More >>Plastic Bottle Syrup Filling Line

The production line consists of the following equipment: JKLP Unscrambler, JKGT-1 Filling and Screw Capping Machine, (SR-6000A Aluminum foil sealing machine) and JKLT Vertical Adhesive Labeling Machine. This integrated line offers automatic bottle unscrambling, filling, capping, aluminum foil sealing, and labeling, making it ideal for 20-500 ml round plastic bottles.

Learn More >>The automatic counting machine is designed specifically for counting tablets, soft gelatin capsules, hard capsules, and pills.

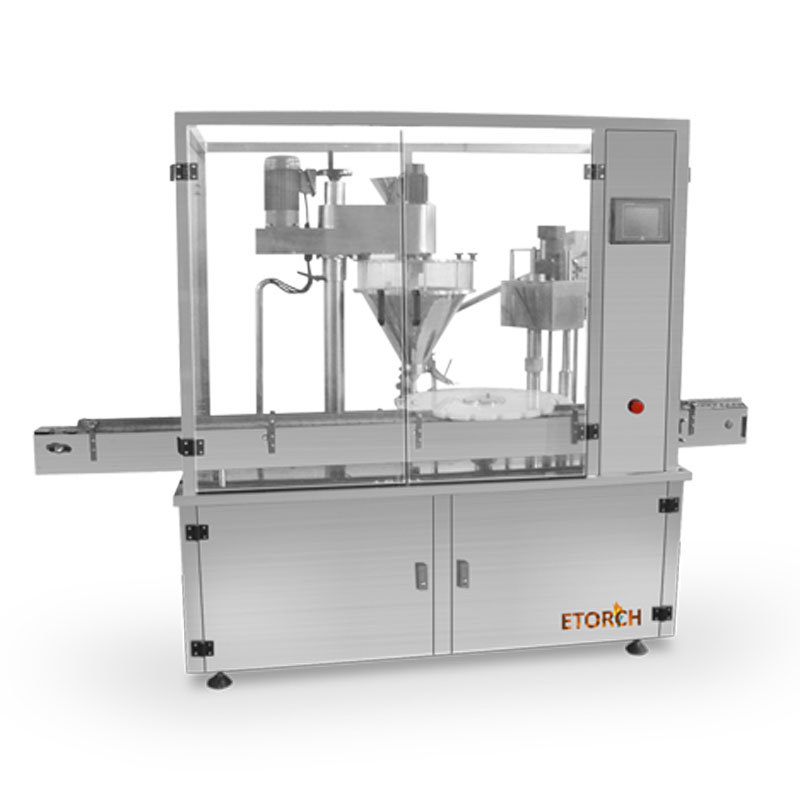

Learn More >>Sterile powder filling machine

Sterile powder filling machine is a new generation of ultra-high speed screw dividing machine developed by our engineering and technical staff.

Learn More >>The Oral Liquid Production Line is designed for efficient processing of pharmaceutical oral liquids. This comprehensive system includes the JKQXL Vertical Washing Machine, JKRX Hot Air Circulating and Sterilizing Tunnel, and JKKF-24 Oral Liquid Filling and Capping Machine. It seamlessly executes washing, drying, sterilizing, filling, and capping functions, ensuring compliance with GMP requirements for high-quality production.

Learn More >>The Sterile Eye Drop filling Line is designed to ensure a seamless process for filling or eye drops. This line consists of several key components, including a bottle unscrambling and feeding unit, ion air washing, filling, stoppering, and capping units. It is engineered to handle a variety of bottle sizes through easy mold changes, allowing for flexible production without the need for specialized tools for disassembly.

Learn More >>Powder Filling/Capping Machine

The JKFZ Powder Filling and Capping Machine is a specialized unit designed for the efficient filling and capping of powder and solid particle products. This machine is suitable for use in the pharmaceutical and food industries, ensuring high productivity and accuracy in packaging.

Learn More >>We mainly produce the automatic filling and sealing machine that use the compound tubes and the plastic tubes inner hot air type and outer hot type, It can accomplish the operation of two edge folds three edge folds and saddle-shaped edge folds. All kinds of machine are used for pharmaceuticals cosmetics light chemicals.

Learn More >>Diagnostic Reagent Filling Line

Diagnostic reagent filling production line is applicable to production of all kinds of diagnostic reagent in medical and chemical industry. Non-standard design can be conducted according to customer requirements.

Learn More >>The JKPG Spray Filling Machine is engineered for efficient liquid filling in the pharmaceutical, healthcare, and food industries. Its rational design incorporates a servo system and ceramic pump measuring for precise filling, particularly suited for bottles ranging from 3 mL to 25 mL. Constructed from SS316L stainless steel for all contact parts, this machine adheres to GMP requirements, ensuring high standards in hygiene and safety. Key features include automatic functions that prevent operation without bottles, and a flip unit for screw capping that protects the caps from damage.

Learn More >>The standard equipment model table shows the equipment production capacity under the condition of 3bar pure steam pressure and 6bar industrial steam with the unit in kg/h. The actual production capacity of some type equipments shall be acquired in accordance with the actual operation pressure and use this actual operation pressure to multiply the conversion coefficient in the specified production capacity. Public facility demand Industrial saturated steam without impurities and corrosive materials, the maximum pressure is 9bar. Feeding water requires deionized water without silica, chlorine, amine and volatile substance, etc. The pressure required is 1-2bar. Power supply standards: according to the clients’ requirements. Dry, oil-free and clean compressed air, the minimum pressure required is 6bar.

Learn More >>ABOUT US

ABOUT US

ETORCH Group specializes in processing and packaging equipment for liquid products, catering to both non-sterile and sterile applications in the pharmaceutical industry. Our core principle is to deliver the best cost-benefit ratio in the market, making us a trusted partner for high-quality solutions like Liquid Filling Lines, Water Treatment Systems, and Packaging Equipment.

We excel in providing end-to-end project development—from initial concept through to installation, startup, and technology transfer. With ETORCH Group, you can expect customized solutions that align with your specific production needs, supported by world-class technical service and a commitment to operational excellence.

ABOUT US

ETORCH Group specializes in processing and packaging equipment for liquid products, catering to both non-sterile and sterile applications in the pharmaceutical industry. Our core principle is to deliver the best cost-benefit ratio in the market, making us a trusted partner for high-quality solutions like Liquid Filling Lines, Water Treatment Systems, and Packaging Equipment.

We excel in providing end-to-end project development—from initial concept through to installation, startup, and technology transfer. With ETORCH Group, you can expect customized solutions that align with your specific production needs, supported by world-class technical service and a commitment to operational excellence.

Looking For More Information?