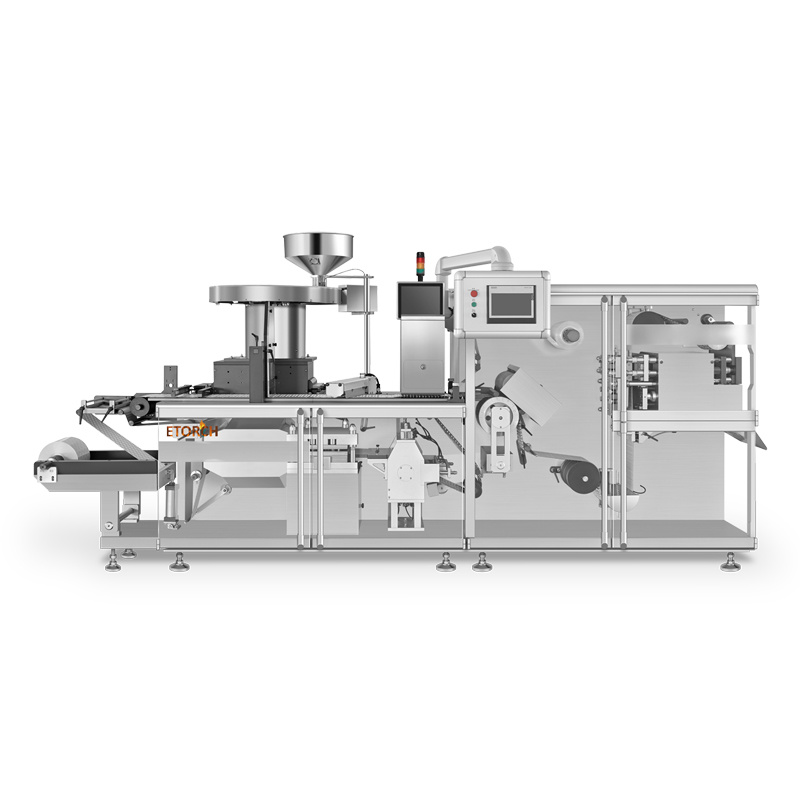

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

BRIEF INTRODUCTION

Product Description

Blister machine DPH260H is a blister packaging machine in the continuous drum sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

The DPH260H is a new generation product developed by our company to meet the high productivity needs of our customers. Its punching times can be 200 times per minute, which is about four times higher than ordinary blister machines.

This high-speed blister machine is equipped with special feeder for shaped pills and edgeless punching, which greatly improves the production efficiency. This high-speed blister machine also has the characteristics of high punching frequency, low energy consumption, accurate and stable action and easy mold change.

Product Description

The molds of the blister machine are positioned by keyway and fixed by pressing plate. Don’t need to adjust the parallelism and left/right movement when installing the forming mold and heat-sealing mold, so it is more convenient to change the mold

This blister machine can be used for both aluminum-aluminum and aluminum-plastic packing (needs to change the mold). And the punching station of this blister machine is designed to punch horizontally, which can reduce the waste edge from punching.

This blister machine adopts variable frequency speed control: (its punching speed can be available from 20 to 50 times/min) Setting the corresponding punching times according to the length of stroke and the difficulty of filling materials, etc.

The stroke of the blister machine is adjustable. And the servo traction device is optional.

This blister machine adopts compressing pair heating-plates, which shortens the heating length of the plastic film and reduces the heating power and temperature, thus enhancing the stability of the plastic film.

Upper and lower mesh plates (concave and convex) cooperate for heat sealing (also can be line seal), due to equal stress, the curling phenomenon of blisters is avoided, meanwhile the sealing performance is improved.

All parts in contact with medicine are made of stainless steel and non-toxic materials and are meeting “GMP” requirements.

The production line with EMERGENCY STOP device, electronic counting, batch number, punching, automatic stopping and alarming if the film is used up or broken, etc. And has a smooth process and intuitive production process.

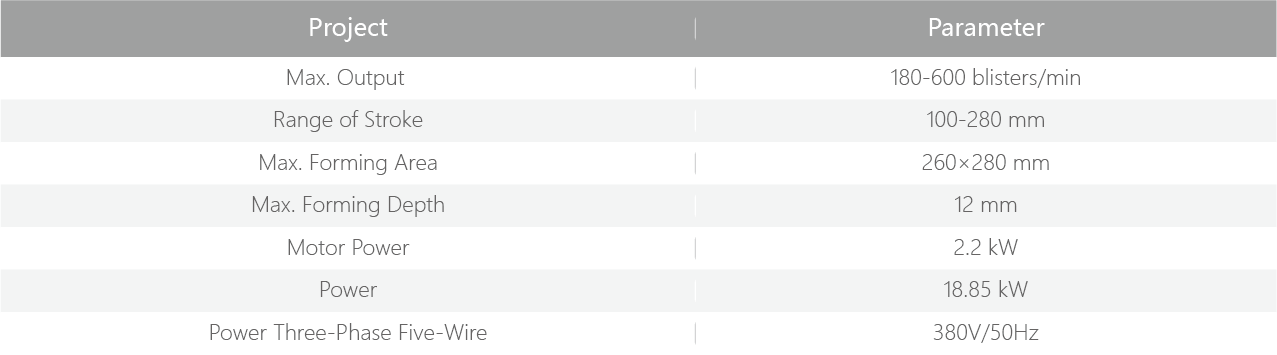

Technical Data

*The above parameters are for reference only, please contact sales for actual parameters.

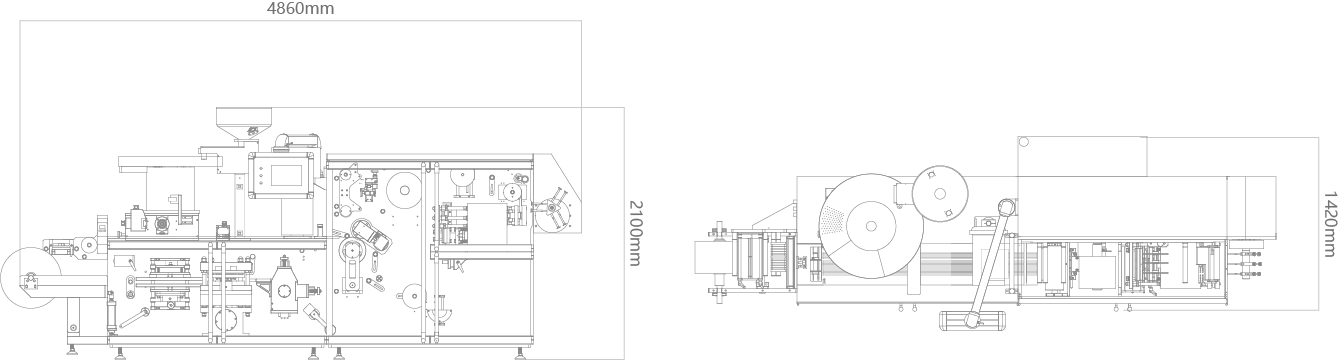

Dimension

GIVE US A MESSAGE