Vial Filling Line

BRIEF INTRODUCTION

PRODUCT DESCRIPTION

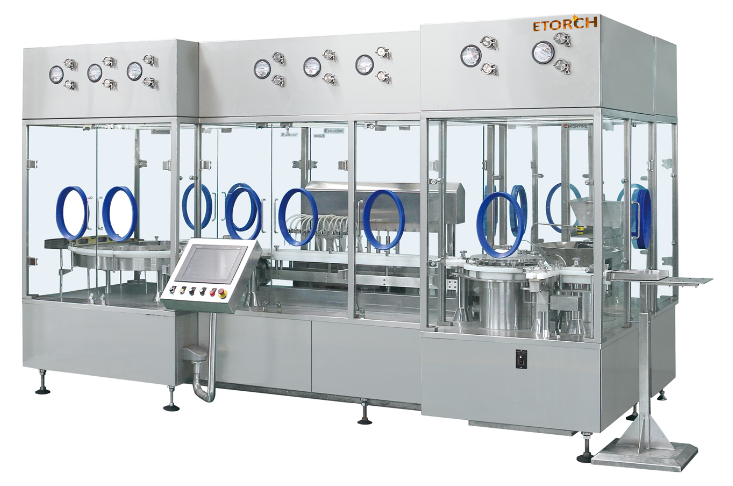

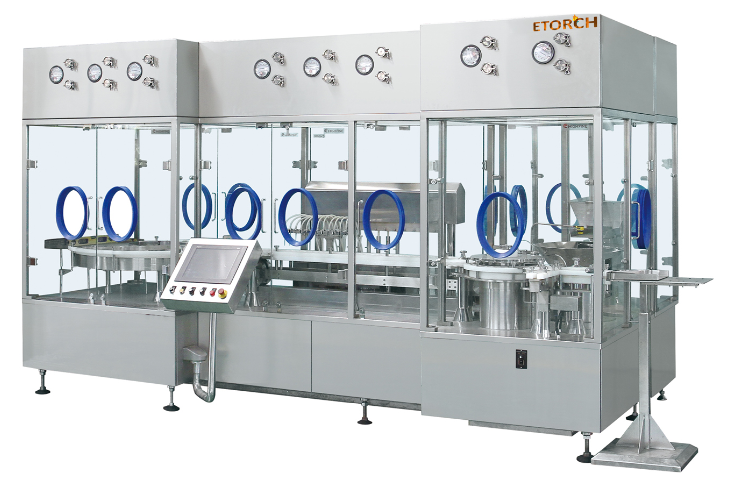

JKFFL Series of Vial Washing-Sterilization-Filling-Stoppering Linkage Line

The linkage line integrates the JKQX series vertical ultrasonic washing machine, JKRX series hot air circulation sterilization tunnel, and JKFF series filling and stoppering machine, and JKZ capping machine. It can function as a complete line or as individual machines. It provides water spray filling, ultrasonic cleaning, water flushing (internal and external), compressed air flushing (internal and external), preheating, drying, sterilizing, pyrogen removal, cooling, filling, stoppering, and capping processes.

This line is compatible with vials ranging from 2-30mL, ensuring thorough washing, drying, pyrogen removal, filling, and sealing processes.

CHARACTERISTICS

The vertical ultrasonic washing machine employs ultrasonic rough washing, circulating water, WFI, and clean compressed air for alternate spraying and cleaning of containers. It achieves optimal clarity and inspection results, making it a popular choice worldwide.

The sterilization tunnel uses a hot air laminar flow and high-temperature sterilization process for preheating, drying, sterilizing, and pyrogen removal. It is widely regarded as a leading drying and sterilizing solution.

The filling and stoppering machine uses a V-shaped block for stable via transfer and a reciprocating tracking filling method to ensure precise filling volume. The progressive stoppering mechanism ensures high stoppering accuracy, making it a preferred choice globally.

The linkage production line features PLC control and a touch screen interface, offering both integrated and stand-alone operation modes with stable control and high automation.

JKQX Series Vertical Ultrasonic Bottle Washing Machine

MAIN APPLICATION

The JKQX series vertical ultrasonic bottle washing machine is ideal for cleaning vial bottles in pharmaceutical production. It can also clean containers such as ampoules and oral liquid bottles.

JKRX Series Hot Air Circulation Sterilizing Tunnel

MAIN APPLICATION

The JKRX series tunnel-type hot air circulation sterilization tunnel is designed for drying, sterilizing, and removing heat sources from vials in pharmaceutical production. It can also be used for ampoules and oral liquid bottles.

CHARACTERISTICS

This tunnel features three sections: preheating, high-temperature sterilization, and cooling. It employs hot air laminar flow and high-temperature sterilization for effective drying, sterilization, and depyrogenation. Its negative pressure sealing design and innovative air diversion system ensure uniform thermal distribution, making it a leading choice in drying and sterilization equipment.

JKFF Series Filling and Stoppering Machine

MAIN APPLICATION

The JKFF series filling machine is ideal for filling freeze-dried powder vials in pharmaceutical production. It also supports water filling and stoppering for vials.

CHARACTERISTICS

This machine is equipped with a single or dual synchronized belt and a V-type block, ensuring smooth via transfer. Its reciprocating tracking filling method ensures stability, precise filling, and ampoule filling line. The progressive stoppering system delivers exceptional accuracy, making it the preferred choice for filling and stoppering machines.

JKZ Series Capping Machine

MAIN APPLICATION

The JKZ series capping machine is suitable for capping vials in pharmaceutical production, as well as oral liquid bottles.

CHARACTERISTICS

The machine utilizes one, three, or multiple sealing blades for continuous capping of vials. It performs vial feeding, cap feeding, capping, and vial output in one process. Equipped with a crimping dust exhaust device and driven by a reliable continuous variable motor with an electronic cam, it is compact, stable, and easy to maintain, making it a widely used capping solution.

我们的产品

GIVE US A MESSAGE