Non-PVC Film Soft Bag Filling Line

BRIEF INTRODUCTION

PRODUCT INTRODUCTION

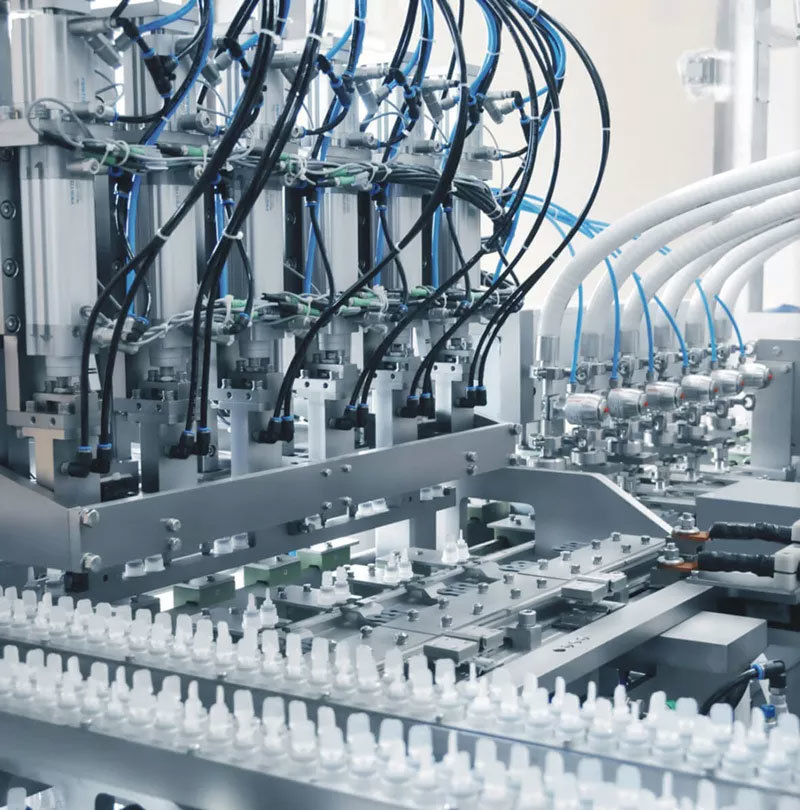

Designed and manufactured by Etorch, the Non-PVC Film Soft Bag Filling Line incorporates advanced technology to deliver high-quality infusion solutions. The use of multi-layer co-extruded films provides numerous benefits, including non-toxicity, compatibility with a variety of liquids, resistance to high and low temperatures, and ease of recycling, contributing to its popularity in global soft bag infusion production.

CHARACTERISTICS

Compact Structure: The design minimizes the cleanroom area required, resulting in lower energy consumption for air conditioning and purification.

Continuous Film-Drawing Technology: Reduces the time taken for bag-making processes, enhancing overall production efficiency.

Adjustable Bag Width: The adjustable bag width feature allows for cost-effective production and improves the aesthetic appearance of the bags.

Servo Mechanism: The main drive motor and long-stroke cylinder utilize a servo mechanism for smooth operation, reduced impact, and enhanced reliability, improving production capacity.

Preheating Mechanisms: Each shaping group includes preheating mechanisms to ensure effective welding and shaping between films from different manufacturers, resulting in minimal leakage rates.

No Contact Transfer Process: During the transfer of soft bags, the inner surfaces do not contact any components, preventing the introduction of foreign particles.

Overall Base Design: The unified base design simplifies installation, reduces debugging time, and facilitates easy cleaning.

GIVE US A MESSAGE