Ampoule Filling Line

BRIEF INTRODUCTION

Product Positioning

Designed to meet GMP-grade production requirements for aseptic pharmaceutical preparations, covering the complete process of ampoule washing → sterilization → filling → sealing.

Applicable Packaging Type & Specifications

Packaging Type: Ampoules

Fill Volume Range: 1 mL – 20 mL

Maximum Output: Up to 24,000 ampoules/hour

(verified under 2 mL ampoule, liquid product conditions)

Process Flow

Infeed → Washing (Ultrasonic washing: 20–43 kHz, water temperature approx. 50 °C) → Sterilization (Dry heat 320 °C, laminar airflow 0.6 m/s, ≥5 min exposure) → Filling (Servo-driven filling, ±0.5% accuracy) → Sealing (Nitrogen pre-flushing protection, rotary flexible flame sealing)

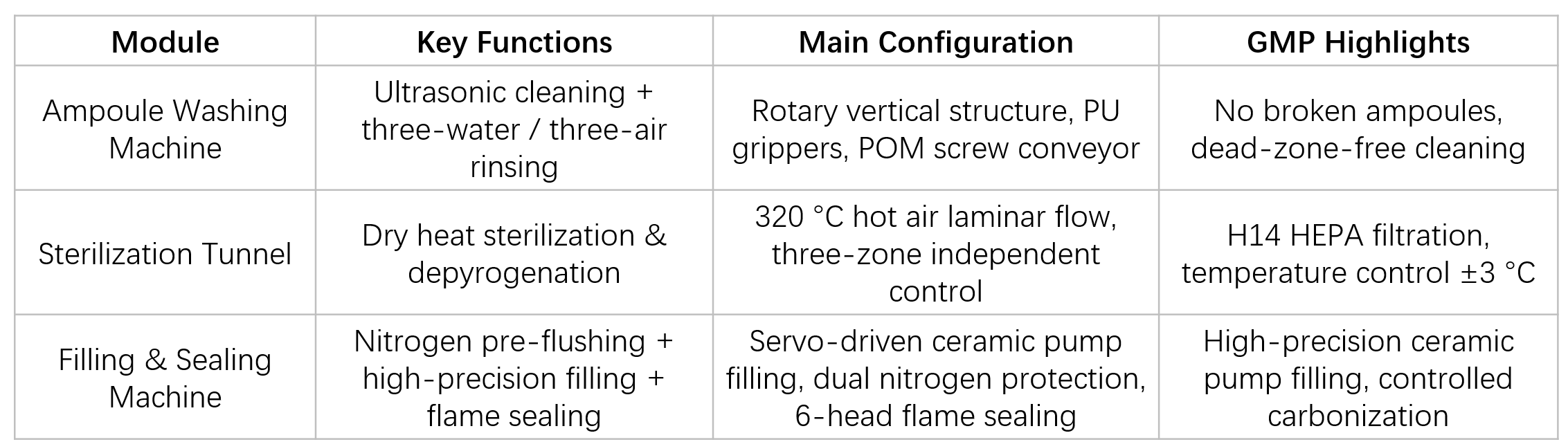

Core Modules

Control System & Data Integrity

The machine is equipped with a Siemens PLC and industrial touch-screen HMI, supporting 21 CFR Part 11–compliant audit trails

Recipe Management, ≥100 recipes stored, one-touch changeover

Batch Record Management, Automatic generation with electronic signatures, PDF export, and MES connectivity via OPC UA

Washing & Sterilization Strategy

The piping system supports WFI recovery, circulation, and filtration, with independent pipelines for WFI and compressed air, eliminating the risk of cross-contamination

Sterilization Cycle, dry heat at 320 °C for 5 minutes, endotoxin reduction ≥3 log

Filtration, HEPA filters supporting DOP testing and resistant to temperatures up to 400 °C

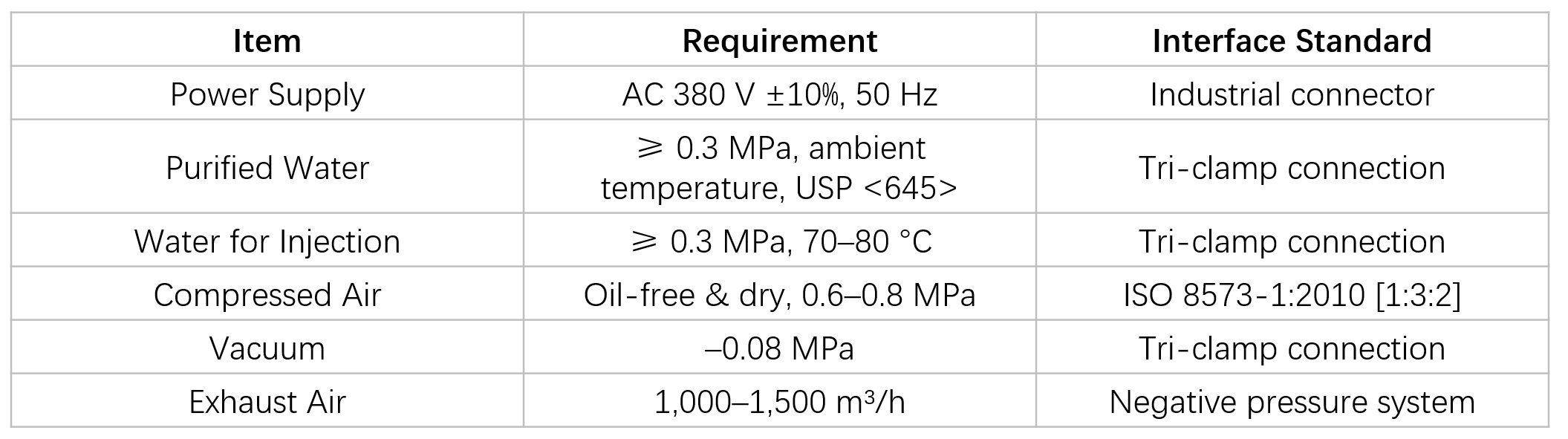

Utility Requirements

JKQX Series Vertical Ultrasonic Bottle Washing Machine

JKRX Series Hot Air Circulation Sterilizing Tunnel

JKAF Series Ampoule Filling and Sealing Machine

GIVE US A MESSAGE