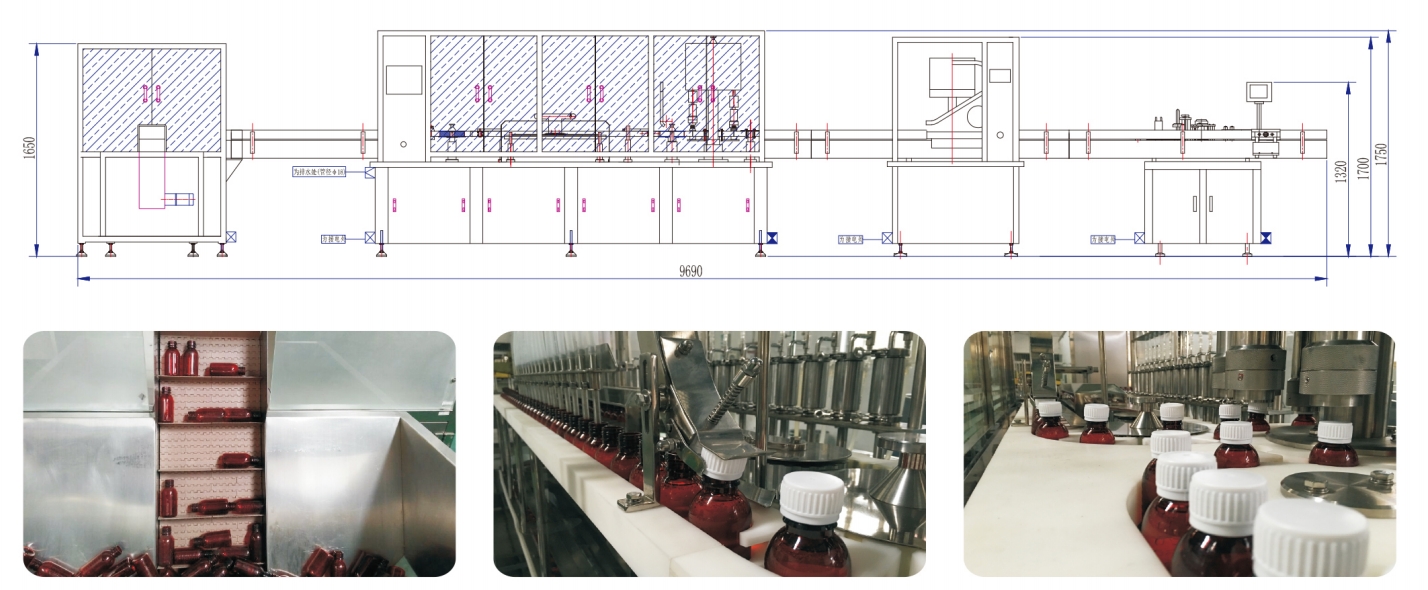

Plastic Bottle Syrup Filling Line

BRIEF INTRODUCTION

Product Positioning

Designed to meet GMP-grade production requirements for oral liquid pharmaceuticals and biological products, covering the complete process of filling / capping / labeling / cartoning.

Applicable Packaging Type & Specifications

Packaging Type: PET bottles / glass bottles / oral liquid bottles

Fill Volume Range: 30 mL – 250 mL

Maximum Output: Up to 12,000 bottles/hour

(verified under 100 mL plastic bottles, syrup product conditions)Parameters

| Model | Adpoted Bottle Size | Porduction Capacity | Power Supply | Sower | Overall Size |

| JKLP-3 | 5-300mL | 150-200 b/min | 220 V 50Hz | 0.5 kW | 1650×2660×1650 mm |

| JKGT-5 | 5-300mL | 150-200 b/min | 380 V 50Hz | 3.5 kW | 4500×2230×1700 mm |

| JKDL | 5-300mL | 150-200 b/min | 220 V 50Hz | 1.0 kW | 2440×1650×1700 mm |

| JKLT | 5-300mL | 150-200 b/min | 220 V 50Hz | 0.8 kW | 2000×1050×1300 mm |

Process Flow

Bottle infeed → Air cleaning (compressed air + vacuum dust removal, 16 blow–suction nozzles) →

Filling (±1% accuracy, servo-controlled piston pumps) → Capping (continuous rotary type with slip protection, acceptance rate ≥99%) → Labeling (accuracy ±1 mm) → Cartoning (up to 220 cartons/min)

Core Modules

| Module | Key Function | Main Configuration | GMP Highlights |

|---|---|---|---|

| Bottle Unscrambler | Automatic bottle feeding | POM conveyor + vacuum bottle turning device | No-bottle stop, automatic restart on bottle supply |

| Cleaning Machine | Air blow–suction dust removal | 16 blow–suction nozzles, compressed air & vacuum system | No bottle–no blowing/suction, acceptance rate ≥99% |

| Filling & Capping Machine | High-precision filling & continuous capping | 16-head servo piston pumps + 10 capping heads | SS 316L pump heads, servo control, no bottle–no filling |

| Labeling Machine | High-speed labeling | Vertical self-adhesive labeling with vision inspection | Siemens PLC control |

| Cartoning Machine | Continuous high-speed cartoning | Servo-driven system + BECKER vacuum pump | CE certified, automatic rejection of defective products |

Control System & Data Integrity

The entire line is controlled by a Siemens PLC with industrial touch-screen HMI, ensuring stable module coordination and easy operation. Sensors cover critical conditions such as missing bottles, missing caps, and line full status, guaranteeing safe and reliable operation.

The system supports multiple recipe presets and one-touch changeover, with automatic recording and export of operation logs and alarm history to meet GMP and audit traceability requirements.

MES integration interfaces (Modbus / OPC) are reserved, and an optional electronic batch record module is available to support digital production management.

Cleaning & Sterilization Strategy

Product-contact parts of the filling system support CIP (Clean-in-Place), achieving ≥99% cleaning coverage with no residual dead zones.

Buffer tanks, filling pumps, and valves are made of 316L stainless steel, fully compliant with GMP cleanliness requirements.

All modules are designed for easy disassembly, allowing efficient manual or in-place cleaning.

Utility Requirements

| Item | Requirement | Interface Standard |

|---|---|---|

| Power Supply | AC 380 V, 50 Hz | Industrial connector |

| Purified Water | ≥0.3 MPa, ambient temperature, USP <645> | Tri-clamp |

| Compressed Air | Oil-free & dry, 0.6–0.8 MPa | ISO 8573-1:2010 [1:3:2] |

GIVE US A MESSAGE