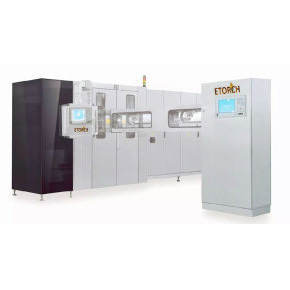

BFS Blowing Filling Sealing Machine

BRIEF INTRODUCTION

PRODUCT INTRODUCTION

The BFS Machine offers a comprehensive solution for aseptic packaging, providing an integrated system that extrudes pharmaceutical-grade materials into bottles, automatically fills them, and seals them—all within a controlled environment. This technology meets the high standards required

for aseptic production, making it suitable for a wide range of applications in the pharmaceutical industry, particularly for plastic bottle sterile liquid preparations.

CHARACTERISTICS:

Aseptic Operation: The system is designed to operate in an environment that minimizes contact with the external environment, ensuring the highest quality of the final product.

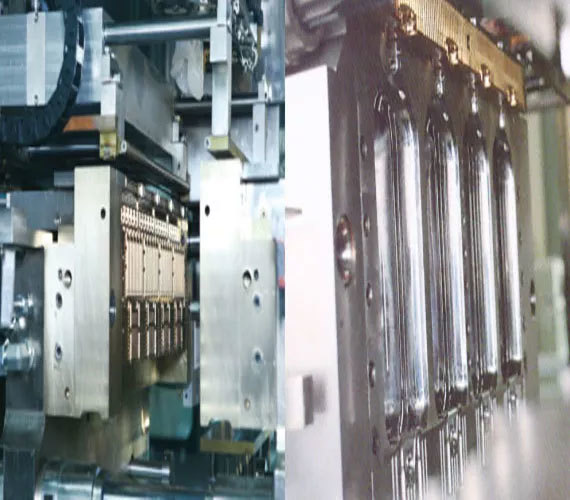

Time-Pressure Filling: Employs a time-pressure quantitative filling system that eliminates moving parts, reducing wear and contamination risks.

Innovative Composite Mandrel: The BFS composite mandrel is powered by a linear motor, eliminating the risk of hydraulic oil leakage and ensuring that no moving parts or seals are present that could contaminate the filling process.

Automatic Online Cleaning: All air and product pipelines can undergo automatic online cleaning and sterilization without manual intervention, maintaining hygiene throughout the process.

Efficient Design: The system can be arranged in black and white partitions, optimizing clean room area and enhancing product safety.

Space-Saving: The compact design occupies less floor space, making it suitable for various production environments.

Modular Construction: The modular design facilitates convenient maintenance and reduces operational costs.

Fully Automated: The equipment operates autonomously, minimizing the need for personnel intervention.

GIVE US A MESSAGE