We mainly produce the automatic filling and sealing machine that use the compound tubes and the plastic tubes inner hot air type and outer hot type, It can accomplish the operation of two edge folds three edge folds and saddle-shaped edge folds. All kinds of machine are used for pharmaceuticals cosmetics light chemicals.

Sterile powder filling machine

Sterile powder filling machine is a new generation of ultra-high speed screw dividing machine developed by our engineering and technical staff.

Pure water equipment requirements:The water quality meets all the provisions of China pharmacopoeia standard and FDA; Automatic equipment operation and conditional automatic processing program (such as back flush, regeneration, acid-washing and disinfection procedures); Monomer and pipe equipment meet GMP requirements (all such back end processing equipments as sterilizer, membrane filtration, terminal water tank and pipeline adopt the 316L material and the pre-treatment pipeline adopts SUS304 material).

Multi-effect Water Distiller System

S series multi-effect water distiller is designed according to theprinciple of falling film and multiple-stage evaporation. The firsteffect is to conduct heating by external heat source (industrial steam)and then each pillar can get enough heat energy by using the purevapor produced from the fore-effect. The material water that did notevaporated in the first effect can be taken as the material in the nexteffect and so on.

The standard equipment model table shows the equipment production capacity under the condition of 3bar pure steam pressure and 6bar industrial steam with the unit in kg/h. The actual production capacity of some type equipments shall be acquired in accordance with the actual operation pressure and use this actual operation pressure to multiply the conversion coefficient in the specified production capacity. Public facility demand Industrial saturated steam without impurities and corrosive materials, the maximum pressure is 9bar. Feeding water requires deionized water without silica, chlorine, amine and volatile substance, etc. The pressure required is 1-2bar. Power supply standards: according to the clients’ requirements. Dry, oil-free and clean compressed air, the minimum pressure required is 6bar.

The Preparation System is designed for material preparation in industries such as bioengineering, large infusions, oral solutions, and fine chemistry. It effectively mitigates the risks of cross-contamination and product contamination during the preparation process, enhancing production efficiency and product reliability.

Fermentation system included: seed tanks, fermentation tanks, controlling system, air handling system, feeding system, piping system, valves, operating platforms, utilities etc. We manufacture the follow-up processing systems for users. Accoding to the requirements of the users, we can design the fermentation workshop and be responsible for on-site installation and commissioning. Our company also trains the employers for the clients and provide the GMP arguments to help users.

The automatic counting machine is designed specifically for counting tablets, soft gelatin capsules, hard capsules, and pills.

Light inspection and leakage detection machine

The inspection machine is designed for detecting leaks and inspecting vials, ampoules, lyophilized products, soft bags, and BFS ampoules.

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP160F is a blister machine in the intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

DPP260TI is a blister machine in intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

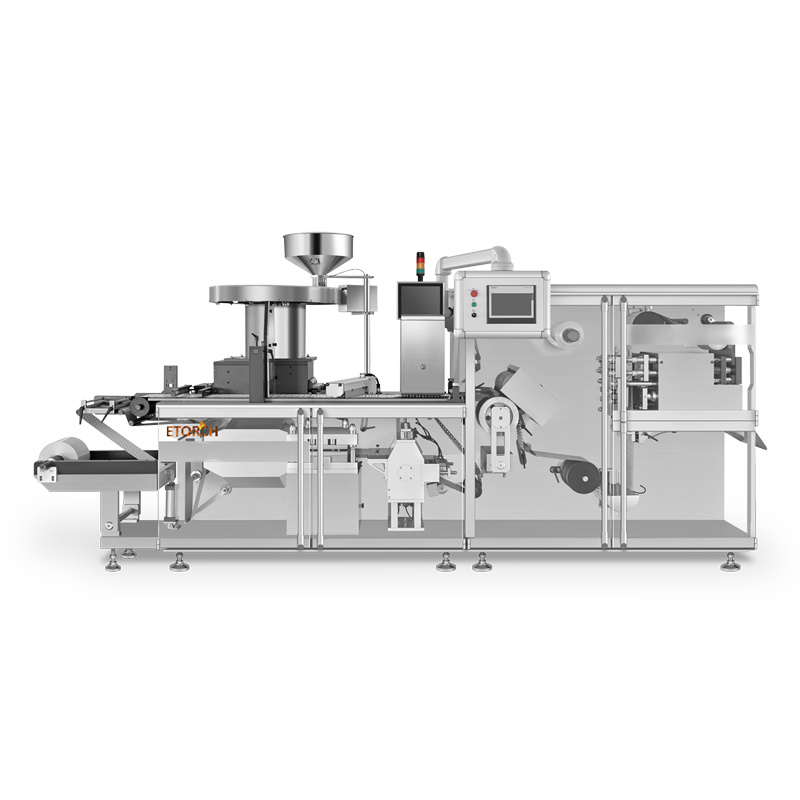

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

Blister packing machine DPH260H is a blister packaging machine in the continuous drum sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

We mainly produce the automatic filling and sealing machine that use the compound tubes and the plastic tubes inner hot air type and outer hot type, It can accomplish the operation of two edge folds three edge folds and saddle-shaped edge folds. All kinds of machine are used for pharmaceuticals cosmetics light chemicals.

Sterile powder filling machine

Sterile powder filling machine is a new generation of ultra-high speed screw dividing machine developed by our engineering and technical staff.

Pure water equipment requirements:The water quality meets all the provisions of China pharmacopoeia standard and FDA; Automatic equipment operation and conditional automatic processing program (such as back flush, regeneration, acid-washing and disinfection procedures); Monomer and pipe equipment meet GMP requirements (all such back end processing equipments as sterilizer, membrane filtration, terminal water tank and pipeline adopt the 316L material and the pre-treatment pipeline adopts SUS304 material).

Multi-effect Water Distiller System

S series multi-effect water distiller is designed according to theprinciple of falling film and multiple-stage evaporation. The firsteffect is to conduct heating by external heat source (industrial steam)and then each pillar can get enough heat energy by using the purevapor produced from the fore-effect. The material water that did notevaporated in the first effect can be taken as the material in the nexteffect and so on.

The standard equipment model table shows the equipment production capacity under the condition of 3bar pure steam pressure and 6bar industrial steam with the unit in kg/h. The actual production capacity of some type equipments shall be acquired in accordance with the actual operation pressure and use this actual operation pressure to multiply the conversion coefficient in the specified production capacity. Public facility demand Industrial saturated steam without impurities and corrosive materials, the maximum pressure is 9bar. Feeding water requires deionized water without silica, chlorine, amine and volatile substance, etc. The pressure required is 1-2bar. Power supply standards: according to the clients’ requirements. Dry, oil-free and clean compressed air, the minimum pressure required is 6bar.

The Preparation System is designed for material preparation in industries such as bioengineering, large infusions, oral solutions, and fine chemistry. It effectively mitigates the risks of cross-contamination and product contamination during the preparation process, enhancing production efficiency and product reliability.

Fermentation system included: seed tanks, fermentation tanks, controlling system, air handling system, feeding system, piping system, valves, operating platforms, utilities etc. We manufacture the follow-up processing systems for users. Accoding to the requirements of the users, we can design the fermentation workshop and be responsible for on-site installation and commissioning. Our company also trains the employers for the clients and provide the GMP arguments to help users.

The automatic counting machine is designed specifically for counting tablets, soft gelatin capsules, hard capsules, and pills.

Light inspection and leakage detection machine

The inspection machine is designed for detecting leaks and inspecting vials, ampoules, lyophilized products, soft bags, and BFS ampoules.

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP160F is a blister machine in the intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

DPP260TI is a blister machine in intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

Blister packing machine DPH260H is a blister packaging machine in the continuous drum sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine