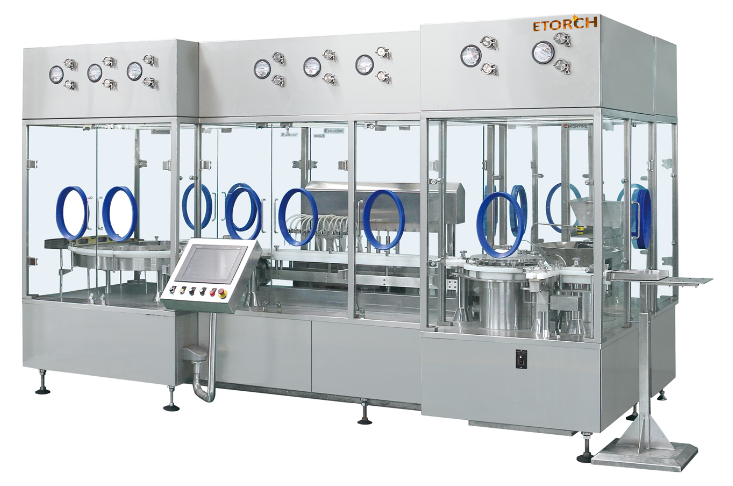

Vial Filling Line

BRIEF INTRODUCTION

Product Positioning

Designed to meet GMP-grade production requirements for aseptic preparations, covering the entire process of vial washing → sterilization → filling → stopper insertion → capping.

Applicable Packaging Type & Specifications

Packaging Type: Vials

Fill Volume Range: 2 – 100 mL

Maximum Output: Up to 18,000 vials/hour

(verified under 10 mL vial, liquid product conditions)

Process Flow

Infeed → Washing (Ultrasonic + Three-Water / Three-Air Spray) → Sterilization (Dry heat at 320 °C, laminar airflow 0.6 m/s, exposure time ≥ 5 minutes) → Filling (Servo-driven filling, ±0.5% accuracy, optional in-line check weighing) → Stoppering (Vacuum stoppering) → Capping (Capping acceptance rate ≥99.97%)

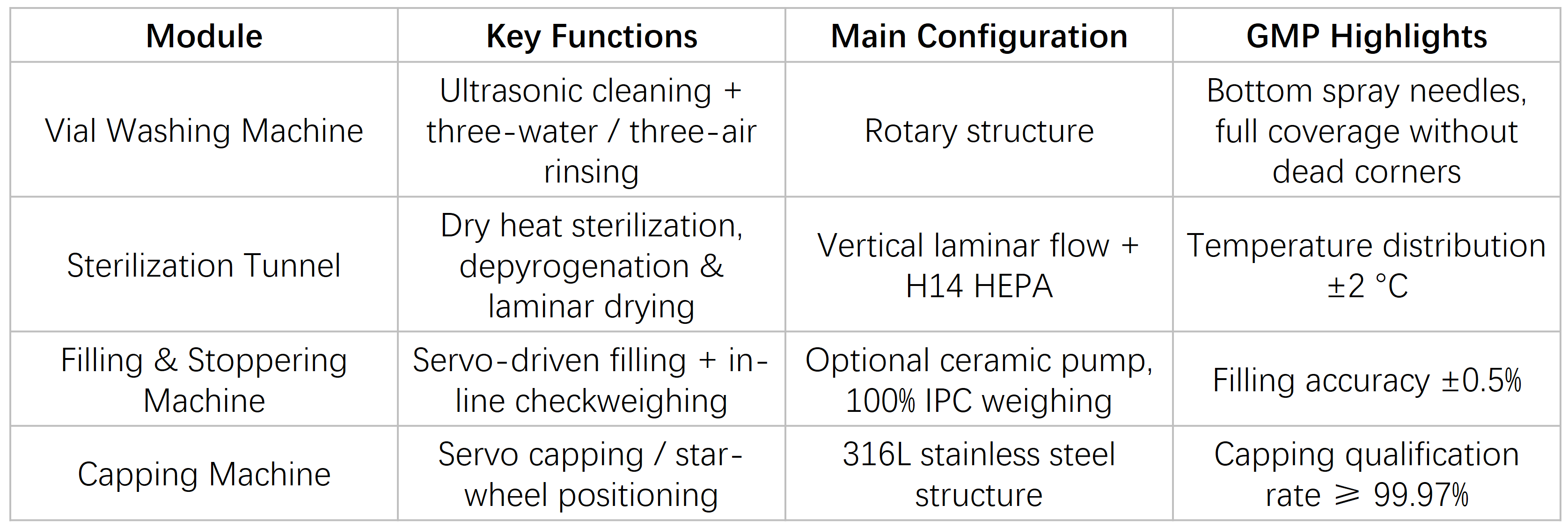

Core Modules

Control System & Data Integrity

All machines in the line are controlled by PLC systems with touch-screen HMI, supporting parameter setting, alarm management, and real-time status monitoring.

The filling machine is equipped with closed-loop control via in-line check weighing; the sterilization tunnel allows export of temperature profiles for validation purposes.

Selected modules are MES-ready and can be customized for system integration.

Washing & Sterilization Strategy

The bottle washing machine adopts triple-water triple-air + ultrasonic cleaning, with full-coverage water and air spray needles leaving no dead corners, supporting multi-stage purified water/WFI rinsing.

The sterilizing tunnel adopts dry heat sterilization at 320°C, with laminar airflow velocity of 0.6 m/s and sterilization time ≥5 minutes. It features three independent temperature zones, supports heat distribution validation, and achieves endotoxin reduction ≥6 log.

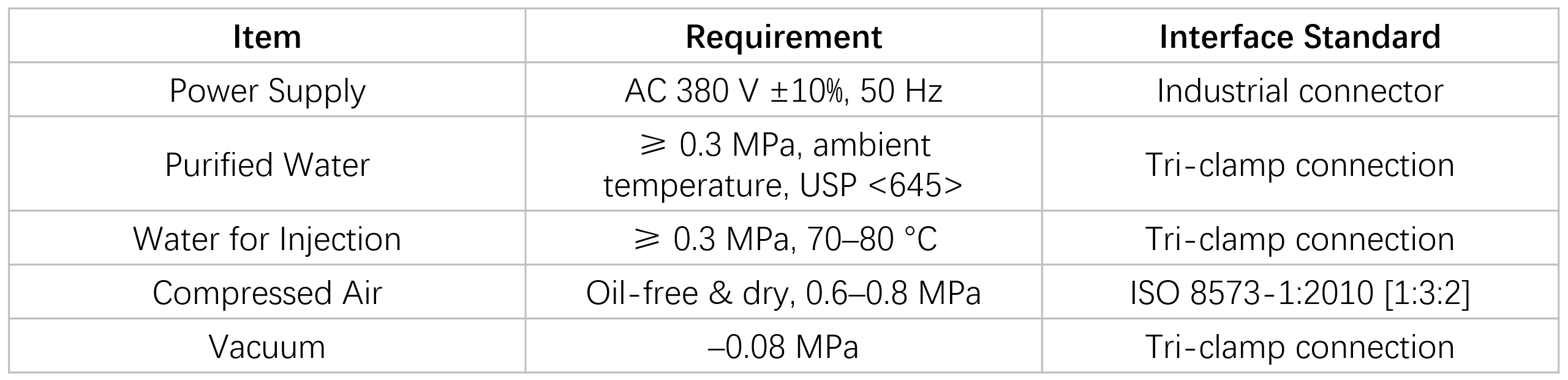

Utility Requirements

JKQX Series Vertical Ultrasonic Bottle Washing Machine

JKRX Series Hot Air Circulation Sterilizing Tunnel

JKFF Series Filling and Stoppering Machine

JKZ Series Capping Machine

我们的产品

GIVE US A MESSAGE