Sterile Powder Filling Machine

BRIEF INTRODUCTION

Standalone Machine Positioning

Designed to independently perform aseptic filling / stoppering / crimping operations, fully meeting GMP requirements for standalone aseptic production.

Applicable Packaging & Specifications

Container type: Vials (tubular glass vials)

Filling range: 2 – 100 mL

Output: 9,000 vials/hour

(Measured under operating conditions of 10 mL vials with powder products)

Process Flow

Bottle unscrambling → In-machine operations: online air blowing + plasma dust removal → A-grade laminar airflow hood with magnetic levitation positioning → servo-driven screw-type aseptic filling → Vacuum stoppering → servo-controlled crimping → Online check weighing → Bottle discharge

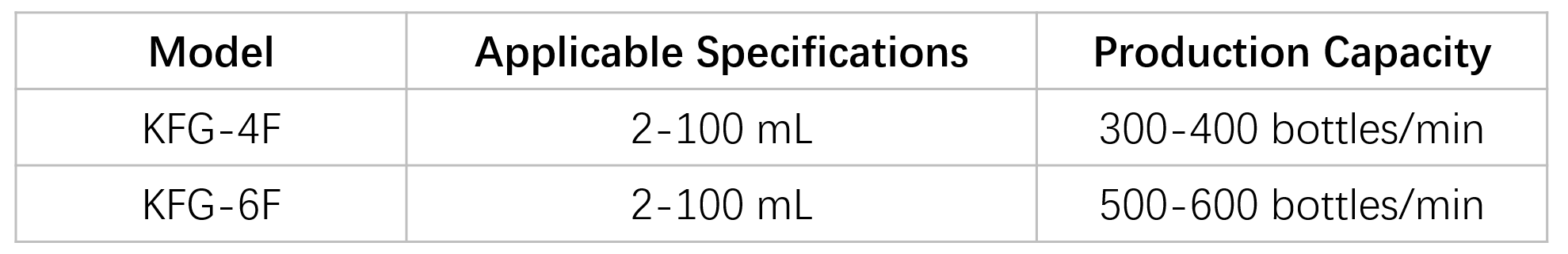

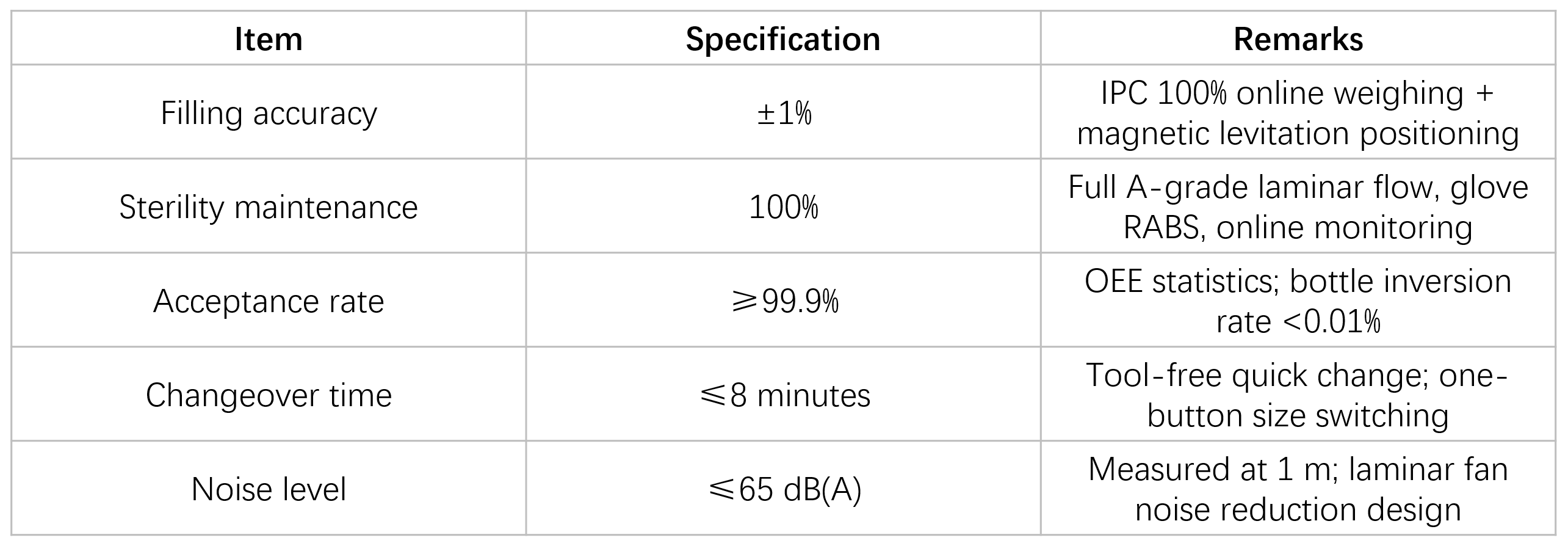

Key Performance Parameters

Structure & GMP Design

Fully enclosed 316 stainless steel frame, electropolished to Ra ≤0.4 μm, featuring zero dead corners and no exposed screws.

Top-mounted ISO Class 5 (Grade A) laminar airflow hood with airflow velocity of 0.35–0.45 m/s; side-mounted RABS glove box enables isolated operation.

All interfaces use quick-clamp connections, supporting online CIP/SIP and VHP (vaporized hydrogen peroxide) sterilization.

The bottle discharge area is equipped with a continuous bag-out system, preventing disruption of the Grade A environment.

Control System

Beckhoff TwinCAT PLC combined with a Siemens 15" color HMI, supporting ≥100 recipe sets.

Full compliance with 21 CFR Part 11, including audit trails, electronic signatures, PDF batch records, and USB/Ethernet data export.

Real-time monitoring of particle counts, airflow velocity, and differential pressure, with seamless integration to OPC UA / MES / LIMS systems.

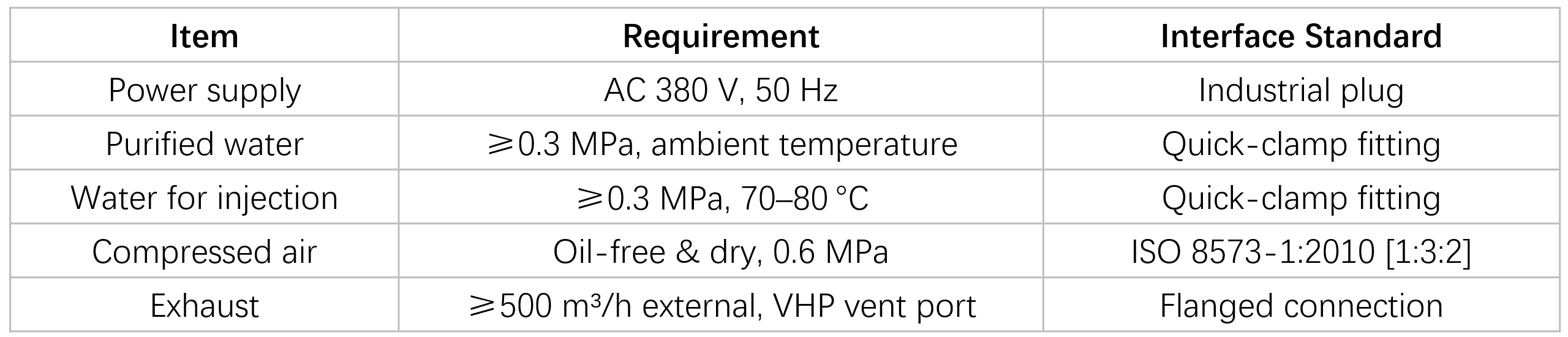

Utility Requirements

GIVE US A MESSAGE