PS Generator

BRIEF INTRODUCTION

Standalone Positioning

Independently completes the Pure Steam generation process, fully meeting GMP requirements for standalone operation.

Applicable Steam Types & Capacity

Steam Types:

① Pure Steam (PSG)

② Clean Steam (CSG)Capacity Range:

PSG (Pure Steam): 100–2,000 kg/h

CSG (Clean Steam): 200–1,600 kg/h

(at 3 bar operating conditions)

Process Flow

Manual / Feed Water Supply → Integrated Process of This Unit: Preheating → Dry Distillation / Fully Immersed Plate-and-Shell Heat Exchange → Continuous Non-Condensable Gas Removal → Precise Pressure Regulation → Pure Steam / Clean Steam Output → Online Condensate Conductivity Monitoring → Automatic Blowdown → Qualified Steam Supply

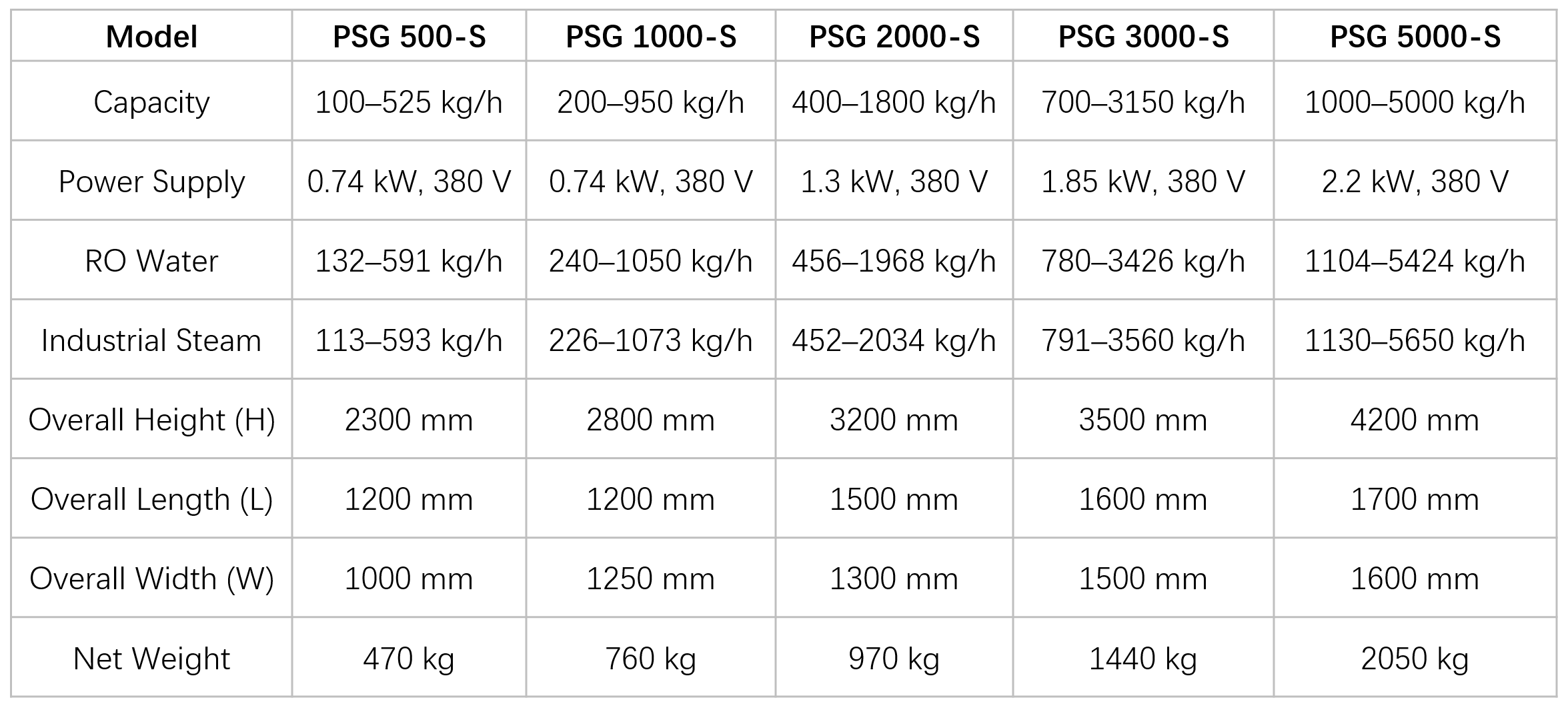

Product Models & Technical Parameters

Construction & GMP Design

Fully 316L stainless steel frame, electropolished with Ra ≤ 0.4 μm, sloped surfaces for zero dead-leg drainage.

Demister-free evaporator design, eliminating secondary contamination risks; fully immersed heating to avoid stress concentration.

Double-layer fully enclosed insulation housing with tempered glass viewing window; pharmaceutical-grade EPDM / PTFE seals.

Modular skid design, reducing footprint by up to 30% compared with conventional boilers.

Control System

Siemens S7-1200 / S7-1500 PLC + 10" color HMI, ≥100 recipes.

21 CFR Part 11 compliant audit trail; USB / PDF batch record export.

Four-parameter online monitoring: conductivity, pressure, level, and temperature, with automatic shutdown and alarm upon abnormal conditions.

Reserved OPC UA / Modbus-TCP interfaces for direct MES / LIMS connectivity.

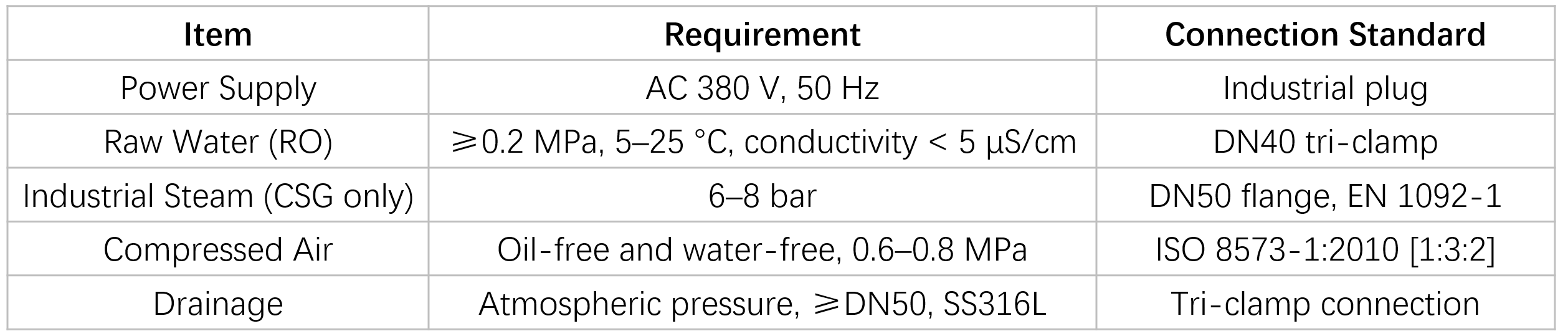

Utility Requirements

GIVE US A MESSAGE