Y-400 Vertical labeling machine

BRIEF INTRODUCTION

Standalone Machine Positioning

Independently performs the labeling process, meeting GMP requirements for standalone production.

Applicable Packaging Types & Specifications

Applicable containers: Vials / eye drop bottles / syrup bottles and other round bottles

Bottle diameter range: Ø10 – 70 mm

Production capacity: 0 – 400 bottles/min

Process Flow

Manual / automatic bottle feeding → Machine process: automatic labeling → Bottle discharge

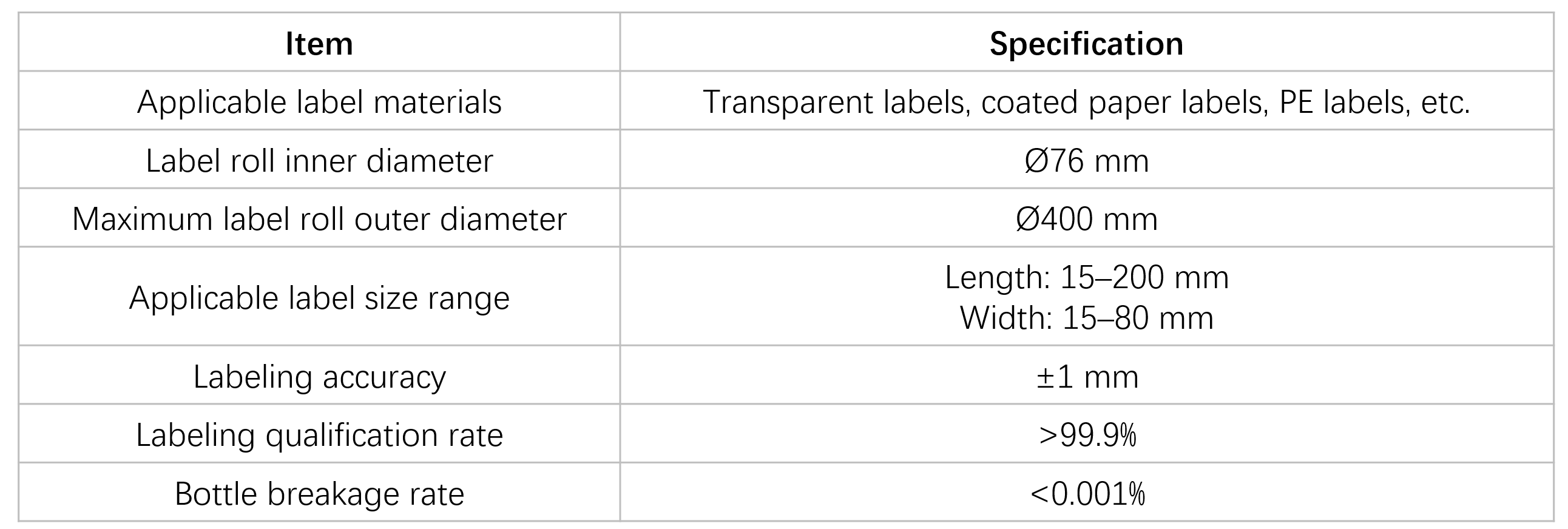

Key Technical Parameters

Structure and GMP Design

This equipment is specifically designed for vertical labeling of round bottles, suitable for vials, syrup bottles, eye drop bottles, and other types of round containers.

The labeling machine head adopts a three-section design, with independent mechanisms for label supply, label pulling, and backing paper recovery, each arranged separately to ensure a neat and orderly label transport process.

A rotary table feeding system is used, offering wide adaptability and easy cleaning, supporting both manual feeding and inline operation, meeting the requirements of different production scenarios.

An optional differential bottle feeding mechanism allows quick adaptation to different product specifications by simply adjusting the mechanism position without changing any parts. A screw-type bottle feeding mechanism can also be optionally installed, providing flexible matching for production needs.

The wheel-mounted belt uses a synchronous belt, and the pressure plate is fitted with cushioning sponge, ensuring smooth operation, excellent buffering performance, and strong label adhesion, while effectively preventing bottle breakage. This design complies with product protection and GMP production requirements.

Control System

The three main mechanisms of the labeling head—label supply, label pulling, and backing paper recovery—are each controlled by an independent motor, ensuring fast and stable label transport, improving labeling accuracy and efficiency.

A touchscreen HMI is provided; in the event of an abnormality, the interface displays real-time fault information and guides troubleshooting, making operation simple and intuitive so that any operator can quickly use the machine.

The system features recipe selection and storage, allowing operators to switch product specifications without resetting parameters by simply calling the corresponding recipe, greatly improving product changeover efficiency.

The machine also supports customizable optional configurations. Users can install online printers, character inspection units, missing-label detection systems, and collection platforms, expanding the functionality and adaptability of the equipment.

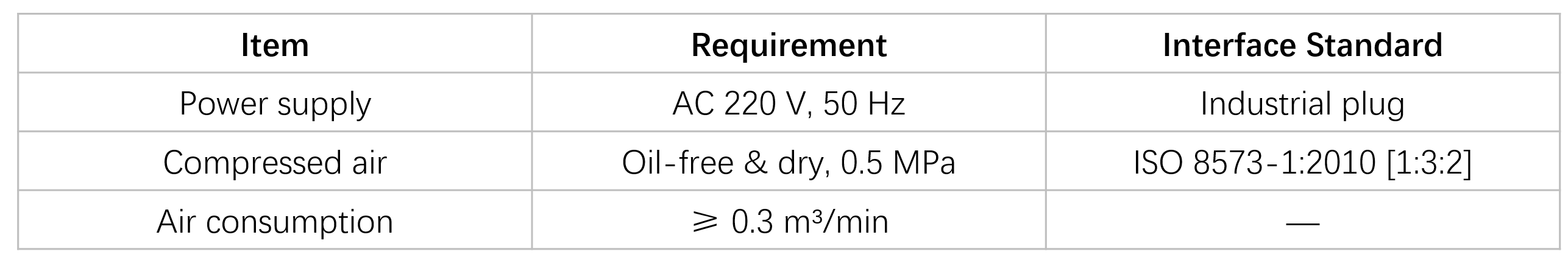

Utility Requirements

GIVE US A MESSAGE