Automatic Counting Machine

BRIEF INTRODUCTION

Standalone Machine Positioning

Designed to independently perform tablet/capsule counting & filling / cap sorting / capping operations, fully meeting GMP requirements for standalone production.

Applicable Packaging & Specifications

Container types: Vials / Oral liquid bottles / Plastic bottles

Filling range: 15 – 500 mL

Output: 12,000 bottles/hour

(Measured under operating conditions of 50 mL bottles with tablet products)

Process Flow

Manual or bottle unscrambler feeding → In-machine operations: photoelectric counting & filling → cap sorting → servo-controlled capping → rejection of non-conforming bottles → Bottle discharge

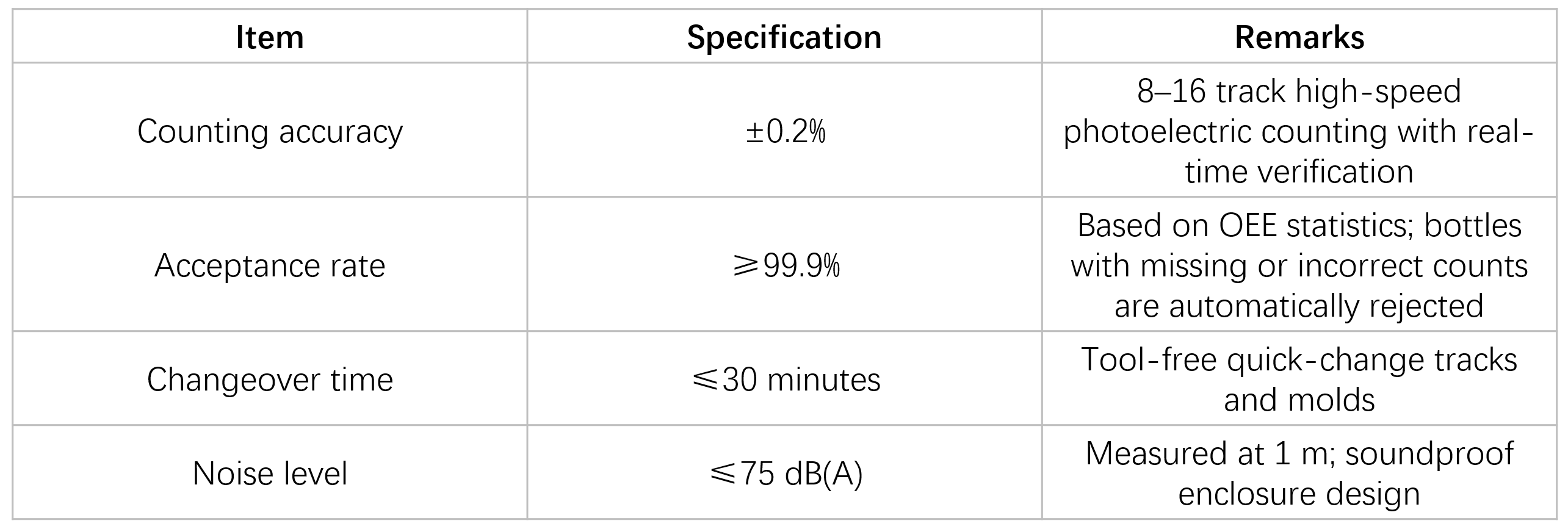

Key Performance Parameters

Structure & GMP Design

316L stainless steel frame, brushed finish with Ra ≤0.4 μm, featuring no hygienic dead corners.

Fully enclosed safety doors with tempered glass viewing windows; all sealing components are pharmaceutical-grade EPDM/PTFE.

Control System

Siemens PLC with 10" color HMI, supporting ≥100 recipe sets.

Full compliance with 21 CFR Part 11, including audit trails and USB/PDF batch record export.

Reserved OPC UA interface for seamless integration with MES/LIMS systems.

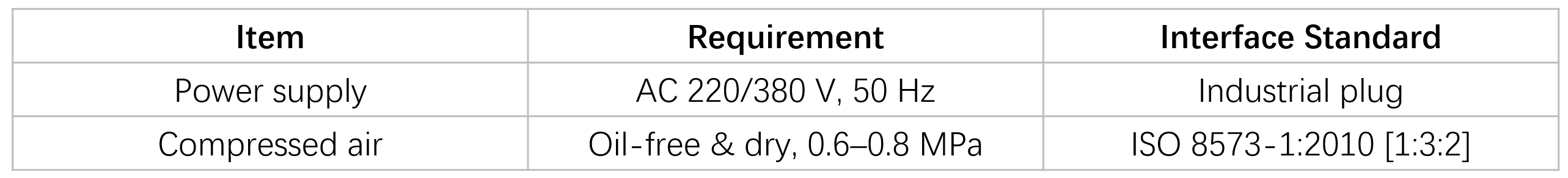

Utility Requirements

GIVE US A MESSAGE