JKFFL Series Vial Filling Line is a modular aseptic production system, composed of a vertical ultrasonic vial washer, a hot air circulation depyrogenation tunnel, a filling and stoppering machine, and a capping machine. The line can operate either as a fully integrated system or as individual standalone units. The complete line covers key processes including washing, drying, depyrogenation and sterilization, filling, stoppering, and capping. It is suitable for vials with volumes of 2–100 mL and meets pharmaceutical production requirements for cleanliness, sterility, and container closure integrity.

JKAFL Series Ampoule Filling Line is an integrated aseptic production system, composed of a vertical ultrasonic cleaning machine, a hot air circulation depyrogenation tunnel, and an ampoule filling and sealing machine. The line can operate either as a fully integrated system or as individual standalone units. The complete line covers key processes including cleaning, drying, depyrogenation and sterilization, filling, and sealing. It is suitable for ampoules with volumes of 1–20 mL and meets pharmaceutical production requirements for cleanliness, sterility, and container closure integrity.

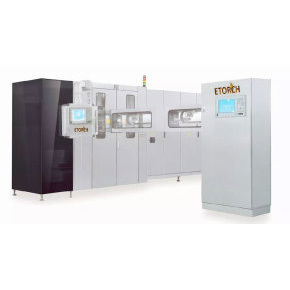

BFS (Blow-Fill-Seal) Machine is an advanced aseptic packaging technology that directly forms containers from pharmaceutical-grade PP/PE pellets and completes blowing, filling, and sealing under fully aseptic conditions throughout the entire process. This technology minimizes manual intervention and environmental exposure, effectively reducing the risk of contamination and ensuring product safety and consistency. It is an ideal solution for the aseptic production of liquid pharmaceutical preparations.

Non-PVC Film Soft Bag Filling Line

The non-PVC soft bag filling production line adopts internationally advanced technology and is specifically designed for the production of infusion products, meeting the requirements of both domestic and international markets. The line uses non-PVC multilayer co-extruded soft bags, which are non-toxic and offer excellent liquid compatibility and superior water vapor barrier properties. The bags can withstand high-temperature sterilization at 121 °C and also exhibit good low-temperature resistance, making them easy to transport and recycle. This solution represents an ideal, environmentally friendly packaging option for infusion products.

Infusion bottle filling production line is an integrated pharmaceutical manufacturing system covering the complete process flow, including bottle unscrambling, washing, drying, sterilization, filling, stopper insertion, capping (crimping/screw capping), and labeling. The line consists of the JKGP Bottle Unscrambler, JKQCX Rotary Ultrasonic Bottle Washer, JKRX Tunnel Sterilization Drying Oven, JKGS Filling and Capping Machine, JKZ Starwheel Positioning Capping Machine, and JKLT Vertical Self-Adhesive Labeling Machine, ensuring stable operation and smooth line integration. It is suitable for infusion bottles with volumes ranging from 20–500 mL. Multiple bottle sizes can be handled through simple mold changeover, allowing flexible adaptation to diverse pharmaceutical production requirements.

Glass Bottle Syrup Filling Line

The glass bottle syrup filling production line is an integrated system designed for the efficient production of pharmaceutical syrups. The complete line consists of key equipment including the JKGP turntable, JKQCX rotary drum ultrasonic bottle washer, JKRX hot air circulation depyrogenation tunnel, JKGT filling and screw capping (crimping) machine, and JKLT vertical self-adhesive labeling machine, enabling fully automated operations from bottle infeed, washing, drying, and sterilization to filling, capping, and labeling. The line is suitable for round glass bottles with volumes ranging from 20–500 mL. With a modular design and quick mold changeover, it can flexibly accommodate different bottle types and sizes. Featuring stable operation, high filling accuracy, reliable sealing, and attractive labeling, the line is equipped with an automated control system and touchscreen HMI for easy operation and high efficiency, making it suitable for both small- to medium-batch and large-scale pharmaceutical syrup production.

Plastic Bottle Syrup Filling Line

The plastic bottle syrup production line is an automated GMP-compliant filling and packaging solution designed for liquid pharmaceutical products such as oral liquids and biological preparations. The line is composed of key equipment including the JKLP Bottle Unscrambler, JKGT-1 Filling and Screw Capping Machine, SR-6000A Aluminum Foil Sealing Machine, and JKLT Vertical Self-Adhesive Labeling Machine, enabling fully automated operations from bottle unscrambling, air rinsing, filling, screw capping, and aluminum foil sealing to labeling and cartoning. The complete line is suitable for 20–500 mL round plastic bottles and is also compatible with PET bottles, glass bottles, and oral liquid bottles. With a modular design and quick format changeover, it can flexibly meet varying product and capacity requirements. Under syrup filling conditions with 100 mL plastic bottles, the maximum output reaches 12,000 bottles per hour.

Oral liquid production line is a GMP-compliant automated manufacturing solution designed for oral liquids, biological products, and other aseptic formulations, meeting high standards for the entire process including bottle washing, sterilization, filling, capping, and labeling. The line is composed of key equipment including the JKQXL Vertical Ultrasonic Bottle Washer, JKRX Series Hot Air Circulation Depyrogenation Tunnel, and JKKF-24 Oral Liquid Filling and Capping Machine, offering compact layout, smooth integration, and stable, reliable operation. The line is suitable for 10 mL glass oral liquid bottles (rubber stopper with aluminum cap) and is also compatible with bottles ranging from 2–50 mL. Quick format changeover allows flexible adaptation for multiple product specifications. Under 10 mL glass bottle water-based conditions, the line can achieve a maximum output of 12,000 bottles per hour.

Eye Drop Filling Line is a GMP-compliant automated filling system designed for aseptic formulations, specifically developed for efficient and stable production of eye drops. It covers the full process from bottle unscrambling, filling, stopper insertion, capping to localized laminar flow protection operations. The line features a compact layout and user-friendly operation, with core equipment including the Filling–Stoppering–Capping Integrated Machine, Bottle Unscrambler, Localized Laminar Flow Hood, Buffer Tank, and Nitrogen Protection System. It supports multiple bottle types and volume specifications, and quick mold changeover allows flexible adaptation to different production requirements. The line is suitable for 5–30 mL eye drop bottles, and under 5 mL water-based eye drop conditions, it can achieve a maximum output of 7,200 bottles per hour.

Diagnostic Reagent Filling Line

Diagnostic Reagent Filling Line is a GMP-compliant automated system designed for in vitro diagnostic (IVD), biochemical, and immunological liquid products, covering the full production process from bottle feeding, air washing, filling, capping to bottle discharge. The line optionally supports visual inspection, labeling, and cartoning, ensuring efficient, stable, and fully traceable production. The system features a compact structure and easy operation, with core equipment including bottle orienting machine, air-washing unit, servo filling machine, servo capping machine, and robotic bottle discharge platform. The line is compatible with multiple packaging types, including round plastic bottles, vials, cartridge bottles, test tubes, and eye-drop bottles, with a capacity range of 2–500 mL. Under 10 mL plastic bottle water-based conditions, the line can reach a peak output of 4,800 bottles per hour.

Spray Filling and Capping Machine

The JKPG Spray Filling Machine is a high-efficiency automated liquid filling solution designed for the pharmaceutical, healthcare, and food industries, specifically for 3–25 mL spray bottles. The machine adopts a servo control system combined with ceramic pump metering technology, ensuring a filling accuracy of ±1%. All liquid-contact components are made of SS316L stainless steel, complying with GMP hygiene standards to guarantee safe and sanitary production. The equipment can independently complete the full process of filling, nozzle insertion, and capping, featuring an intelligent no-bottle no-fill/no-cap protection function to minimize material waste. The screw capping unit is equipped with a flip mechanism to prevent bottle cap damage. The line is suitable for plastic bottles with spray heads, with a capacity range of 10–200 mL. Maximum output reaches 9,000 bottles/hour (tested with 10 mL aqueous spray bottles).

This machine is a standalone tube filling system, specifically designed to independently perform filling, sealing, and batch number printing processes, meeting GMP requirements for standalone production. It is suitable for various tube types, including plastic tubes, composite tubes, and aluminum-plastic tubes, with a capacity range of 5–125 g and an output of up to 5,400 tubes per hour.

JKFFL Series Vial Filling Line is a modular aseptic production system, composed of a vertical ultrasonic vial washer, a hot air circulation depyrogenation tunnel, a filling and stoppering machine, and a capping machine. The line can operate either as a fully integrated system or as individual standalone units. The complete line covers key processes including washing, drying, depyrogenation and sterilization, filling, stoppering, and capping. It is suitable for vials with volumes of 2–100 mL and meets pharmaceutical production requirements for cleanliness, sterility, and container closure integrity.

JKAFL Series Ampoule Filling Line is an integrated aseptic production system, composed of a vertical ultrasonic cleaning machine, a hot air circulation depyrogenation tunnel, and an ampoule filling and sealing machine. The line can operate either as a fully integrated system or as individual standalone units. The complete line covers key processes including cleaning, drying, depyrogenation and sterilization, filling, and sealing. It is suitable for ampoules with volumes of 1–20 mL and meets pharmaceutical production requirements for cleanliness, sterility, and container closure integrity.

BFS (Blow-Fill-Seal) Machine is an advanced aseptic packaging technology that directly forms containers from pharmaceutical-grade PP/PE pellets and completes blowing, filling, and sealing under fully aseptic conditions throughout the entire process. This technology minimizes manual intervention and environmental exposure, effectively reducing the risk of contamination and ensuring product safety and consistency. It is an ideal solution for the aseptic production of liquid pharmaceutical preparations.

Non-PVC Film Soft Bag Filling Line

The non-PVC soft bag filling production line adopts internationally advanced technology and is specifically designed for the production of infusion products, meeting the requirements of both domestic and international markets. The line uses non-PVC multilayer co-extruded soft bags, which are non-toxic and offer excellent liquid compatibility and superior water vapor barrier properties. The bags can withstand high-temperature sterilization at 121 °C and also exhibit good low-temperature resistance, making them easy to transport and recycle. This solution represents an ideal, environmentally friendly packaging option for infusion products.

Infusion bottle filling production line is an integrated pharmaceutical manufacturing system covering the complete process flow, including bottle unscrambling, washing, drying, sterilization, filling, stopper insertion, capping (crimping/screw capping), and labeling. The line consists of the JKGP Bottle Unscrambler, JKQCX Rotary Ultrasonic Bottle Washer, JKRX Tunnel Sterilization Drying Oven, JKGS Filling and Capping Machine, JKZ Starwheel Positioning Capping Machine, and JKLT Vertical Self-Adhesive Labeling Machine, ensuring stable operation and smooth line integration. It is suitable for infusion bottles with volumes ranging from 20–500 mL. Multiple bottle sizes can be handled through simple mold changeover, allowing flexible adaptation to diverse pharmaceutical production requirements.

Glass Bottle Syrup Filling Line

The glass bottle syrup filling production line is an integrated system designed for the efficient production of pharmaceutical syrups. The complete line consists of key equipment including the JKGP turntable, JKQCX rotary drum ultrasonic bottle washer, JKRX hot air circulation depyrogenation tunnel, JKGT filling and screw capping (crimping) machine, and JKLT vertical self-adhesive labeling machine, enabling fully automated operations from bottle infeed, washing, drying, and sterilization to filling, capping, and labeling. The line is suitable for round glass bottles with volumes ranging from 20–500 mL. With a modular design and quick mold changeover, it can flexibly accommodate different bottle types and sizes. Featuring stable operation, high filling accuracy, reliable sealing, and attractive labeling, the line is equipped with an automated control system and touchscreen HMI for easy operation and high efficiency, making it suitable for both small- to medium-batch and large-scale pharmaceutical syrup production.

Plastic Bottle Syrup Filling Line

The plastic bottle syrup production line is an automated GMP-compliant filling and packaging solution designed for liquid pharmaceutical products such as oral liquids and biological preparations. The line is composed of key equipment including the JKLP Bottle Unscrambler, JKGT-1 Filling and Screw Capping Machine, SR-6000A Aluminum Foil Sealing Machine, and JKLT Vertical Self-Adhesive Labeling Machine, enabling fully automated operations from bottle unscrambling, air rinsing, filling, screw capping, and aluminum foil sealing to labeling and cartoning. The complete line is suitable for 20–500 mL round plastic bottles and is also compatible with PET bottles, glass bottles, and oral liquid bottles. With a modular design and quick format changeover, it can flexibly meet varying product and capacity requirements. Under syrup filling conditions with 100 mL plastic bottles, the maximum output reaches 12,000 bottles per hour.

Oral liquid production line is a GMP-compliant automated manufacturing solution designed for oral liquids, biological products, and other aseptic formulations, meeting high standards for the entire process including bottle washing, sterilization, filling, capping, and labeling. The line is composed of key equipment including the JKQXL Vertical Ultrasonic Bottle Washer, JKRX Series Hot Air Circulation Depyrogenation Tunnel, and JKKF-24 Oral Liquid Filling and Capping Machine, offering compact layout, smooth integration, and stable, reliable operation. The line is suitable for 10 mL glass oral liquid bottles (rubber stopper with aluminum cap) and is also compatible with bottles ranging from 2–50 mL. Quick format changeover allows flexible adaptation for multiple product specifications. Under 10 mL glass bottle water-based conditions, the line can achieve a maximum output of 12,000 bottles per hour.

Eye Drop Filling Line is a GMP-compliant automated filling system designed for aseptic formulations, specifically developed for efficient and stable production of eye drops. It covers the full process from bottle unscrambling, filling, stopper insertion, capping to localized laminar flow protection operations. The line features a compact layout and user-friendly operation, with core equipment including the Filling–Stoppering–Capping Integrated Machine, Bottle Unscrambler, Localized Laminar Flow Hood, Buffer Tank, and Nitrogen Protection System. It supports multiple bottle types and volume specifications, and quick mold changeover allows flexible adaptation to different production requirements. The line is suitable for 5–30 mL eye drop bottles, and under 5 mL water-based eye drop conditions, it can achieve a maximum output of 7,200 bottles per hour.

Diagnostic Reagent Filling Line

Diagnostic Reagent Filling Line is a GMP-compliant automated system designed for in vitro diagnostic (IVD), biochemical, and immunological liquid products, covering the full production process from bottle feeding, air washing, filling, capping to bottle discharge. The line optionally supports visual inspection, labeling, and cartoning, ensuring efficient, stable, and fully traceable production. The system features a compact structure and easy operation, with core equipment including bottle orienting machine, air-washing unit, servo filling machine, servo capping machine, and robotic bottle discharge platform. The line is compatible with multiple packaging types, including round plastic bottles, vials, cartridge bottles, test tubes, and eye-drop bottles, with a capacity range of 2–500 mL. Under 10 mL plastic bottle water-based conditions, the line can reach a peak output of 4,800 bottles per hour.

Spray Filling and Capping Machine

The JKPG Spray Filling Machine is a high-efficiency automated liquid filling solution designed for the pharmaceutical, healthcare, and food industries, specifically for 3–25 mL spray bottles. The machine adopts a servo control system combined with ceramic pump metering technology, ensuring a filling accuracy of ±1%. All liquid-contact components are made of SS316L stainless steel, complying with GMP hygiene standards to guarantee safe and sanitary production. The equipment can independently complete the full process of filling, nozzle insertion, and capping, featuring an intelligent no-bottle no-fill/no-cap protection function to minimize material waste. The screw capping unit is equipped with a flip mechanism to prevent bottle cap damage. The line is suitable for plastic bottles with spray heads, with a capacity range of 10–200 mL. Maximum output reaches 9,000 bottles/hour (tested with 10 mL aqueous spray bottles).

This machine is a standalone tube filling system, specifically designed to independently perform filling, sealing, and batch number printing processes, meeting GMP requirements for standalone production. It is suitable for various tube types, including plastic tubes, composite tubes, and aluminum-plastic tubes, with a capacity range of 5–125 g and an output of up to 5,400 tubes per hour.