External Washing and Drying Machine

BRIEF INTRODUCTION

Standalone Machine Positioning

Independently performs the washing process, meeting GMP requirements for standalone production.

Applicable Packaging Types & Specifications

Applicable containers: Vials / infusion bottles / oral liquid bottles / ampoules

Filling volume range: 0.5 – 250 mL

Production capacity: 18,000 bottles/hour

(tested with 2 mL bottles)

Process Flow

Manual / automatic bottle feeding → Machine process: external bottle washing → drying → Bottle discharge

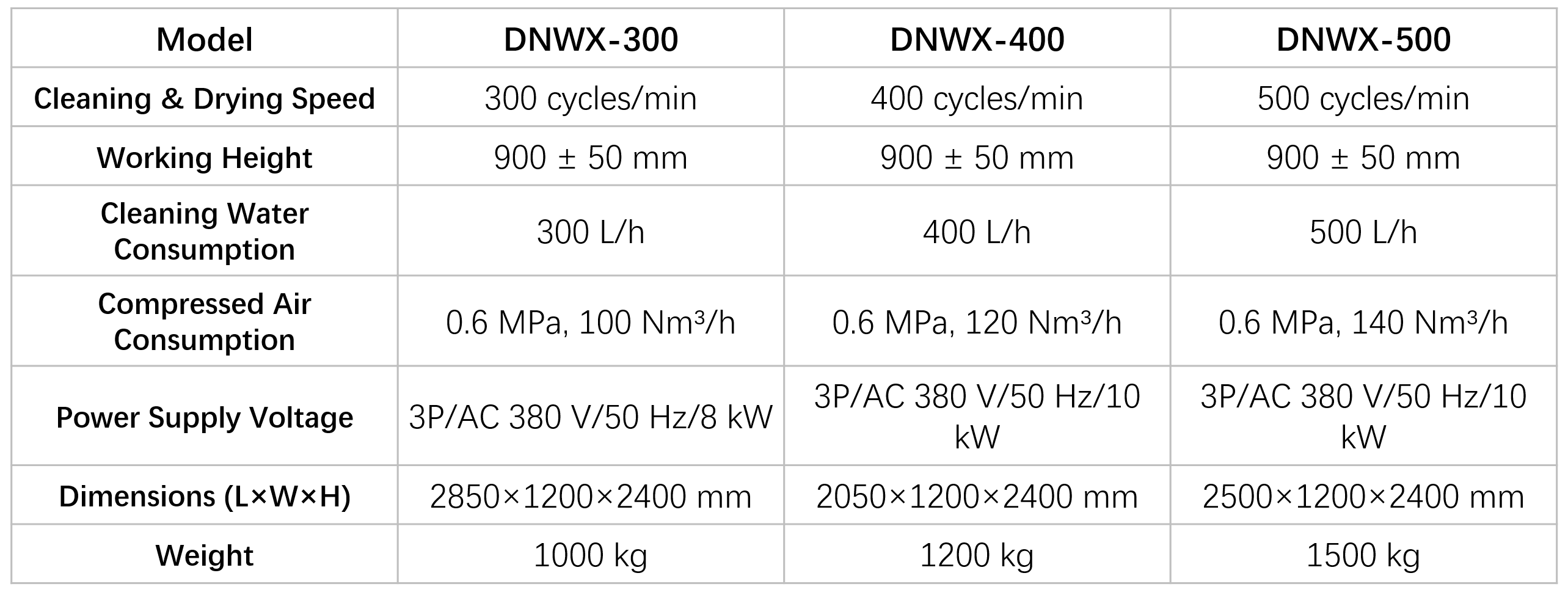

Key Technical Parameters

Structure & GMP Design

The machine can be combined with other equipment to realize online continuous processing or standalone operation in downstream bottle handling, offering flexible layout options suitable for multi-product production.

The equipment operates in a fully enclosed aseptic environment, effectively preventing contamination and reducing pyrogen risk, fully complying with GMP requirements.

All pipelines and valves are made of 316L stainless steel, providing excellent corrosion resistance and high-temperature durability.

Control System

PLC automatic control with a touch-screen HMI, enabling easy parameter setting and visualized operating status

Precise adjustment of washing solution pressure, hot air pressure, and airflow, with real-time monitoring of drying temperature to ensure optimal washing and drying performance

High cleaning efficiency, supporting batch record storage and export

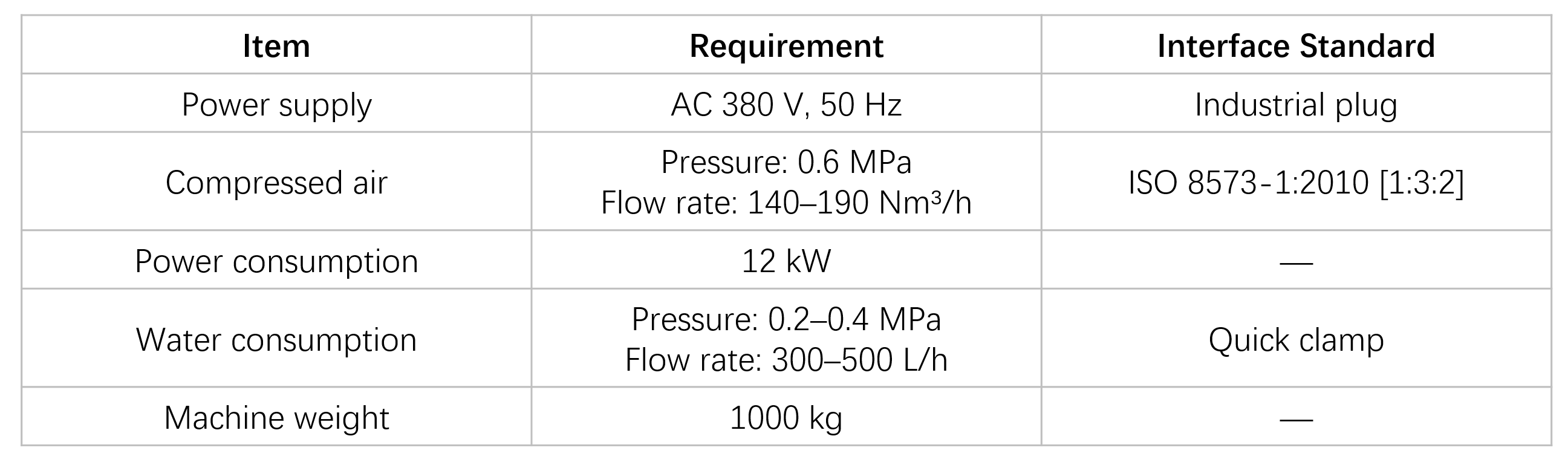

Utility Requirements

GIVE US A MESSAGE