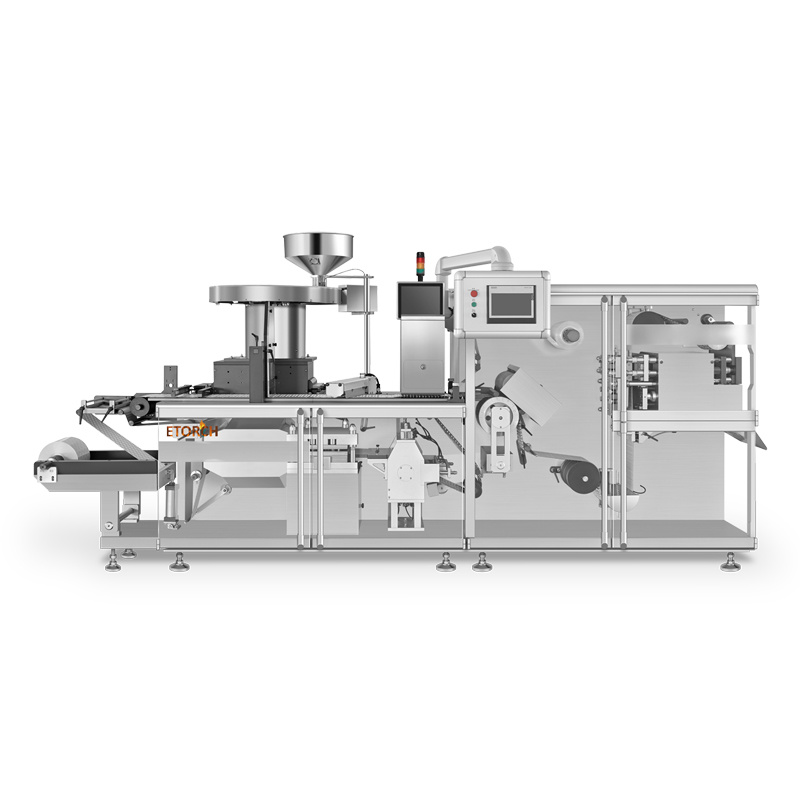

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

BRIEF INTRODUCTION

Standalone Machine Positioning

Independently performs blister packaging with aluminum (PTP) / plastic (PVC) composite sealing for pharmaceutical products (tablets, capsules), medical devices, and healthcare products, fully compliant with GMP requirements.

Applicable Packaging Types & Specifications

Packaging formats:

Alu / Plastic (PVC) blister packs

Alu / Alu (PTP) blister packs

Production capacity: 10,800 – 36,000 blisters/hour

Punching speed: 60 – 200 cycles/min

Feed stroke range: 20 – 100 mm

Maximum forming area: 260 × 280 mm²

Maximum forming depth: 10 mm

Standard blister size: 80 × 57 × 3 mm

Process Flow

Manual / automatic feeding → Machine process: mechanical forming → automatic feeding → sealing → punching → embossing → blister cutting → Discharge

Key Performance Parameters

Structure & GMP Design

Upgraded High-efficiency Heat-sealing System: Utilizes roller heat-sealing technology with small contact area to achieve higher sealing pressure and faster speed. The heat-sealing rollers are equipped with internal constant-temperature heating tubes and an air-cooling system, eliminating risks of water-cooling leakage and enhancing sealing stability.

Servo Step Cutting & Zero-adjustment Format Change: Front and rear step molds are fully servo-synchronized for consistent plate length and automatic alignment. Changing specifications requires only dial adjustment without replacing gears. Misalignment reduction can save approximately 400,000 units of material annually, and plates are automatically and orderly discharged for easy cartoning.

Automatic Lubrication & Comprehensive Fault Protection: Oil pump provides timed automatic lubrication during operation, reducing wear and extending service life. Multiple stoppage protections are included for missing PVC/aluminum foil, missing tablets, insufficient pressure, or over-temperature, with real-time fault display on the touchscreen for rapid troubleshooting.

High-precision Batch Numbering & Safety Enhancements: Supports multiple font options with strong and accurately positioned batch codes. PVC breakage alarms and emergency stop design improve mold change and commissioning safety. All product-contact parts are made of stainless steel and non-toxic materials, fully compliant with GMP standards.

Control System

Siemens PLC with color touchscreen supports at least 100 product recipes for fast product changeover

Compliant with 21 CFR Part 11, featuring audit trail functionality and batch record export in USB/PDF format to ensure full traceability

OPC UA interface reserved for integration with MES / LIMS systems

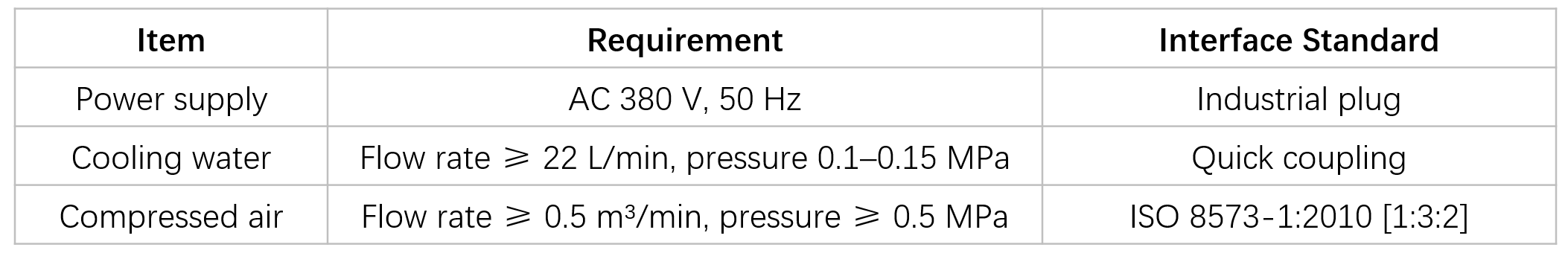

Utility Requirements

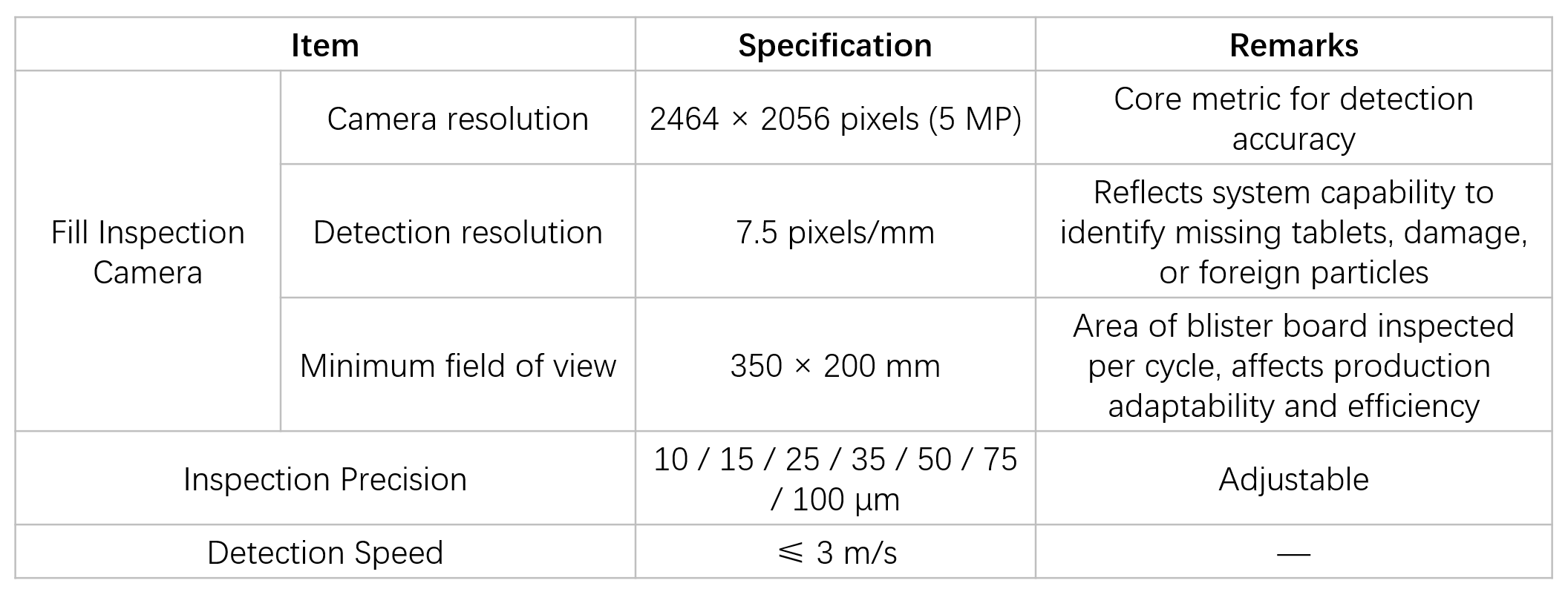

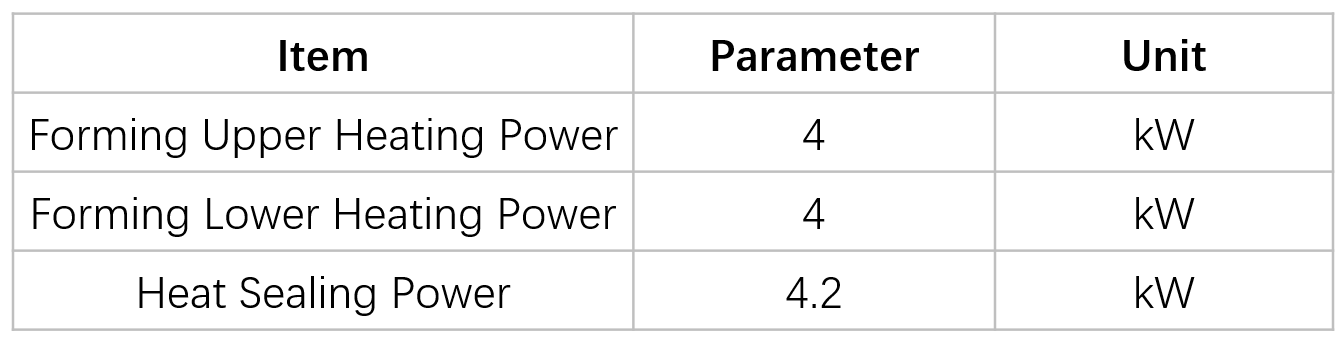

Technical Parameters

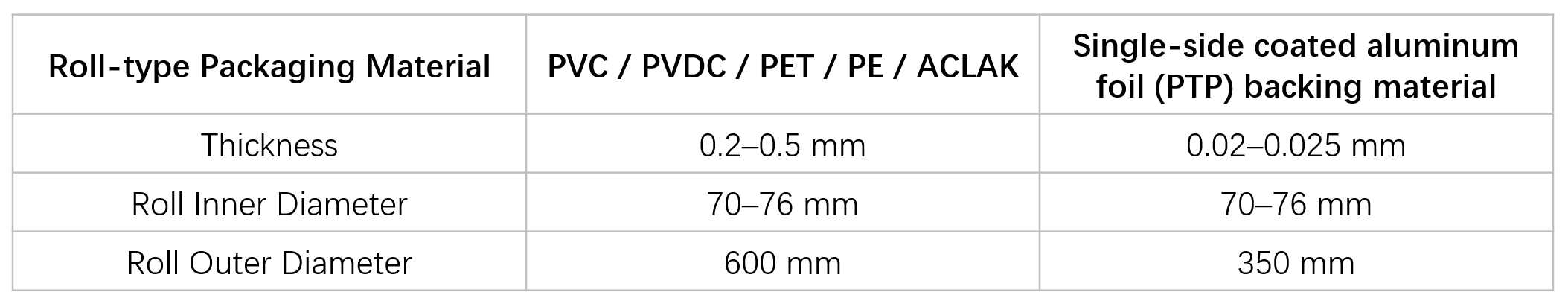

Specifications of Applicable Packaging Materials

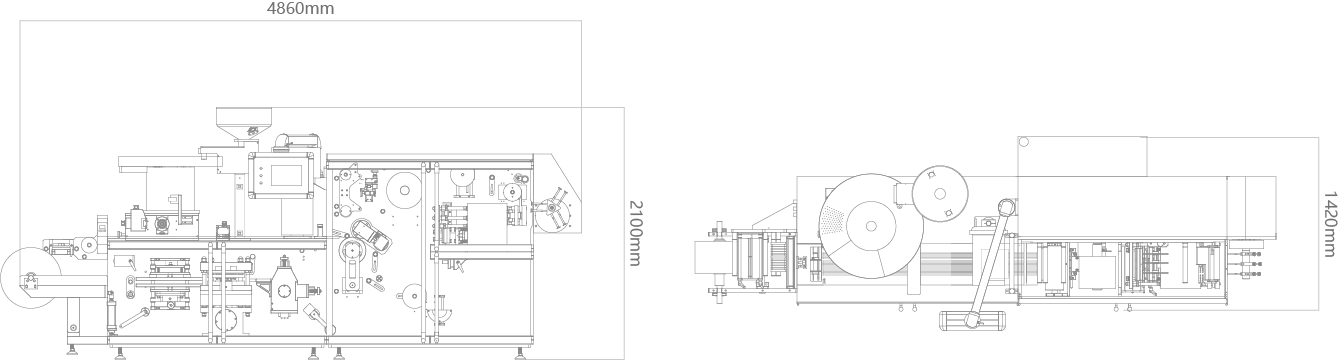

Dimensions

GIVE US A MESSAGE