Fermenter

BRIEF INTRODUCTION

Standalone Positioning

Independently performs sterilization / fermentation processes, meeting the GMP requirements for standalone equipment.

Applicable Capacity & Specifications

Working Volume Range: 30 – 10,000 L (filling ratio 70–80%)

Production Capacity: Batch cycle 5–7 days

Process Flow

Manual Charging / Charging via Inlet Port → Integrated Process of This Unit: In-situ Steam Sterilization → Parameter Setting → Automatic Fermentation & Cultivation → Discharge

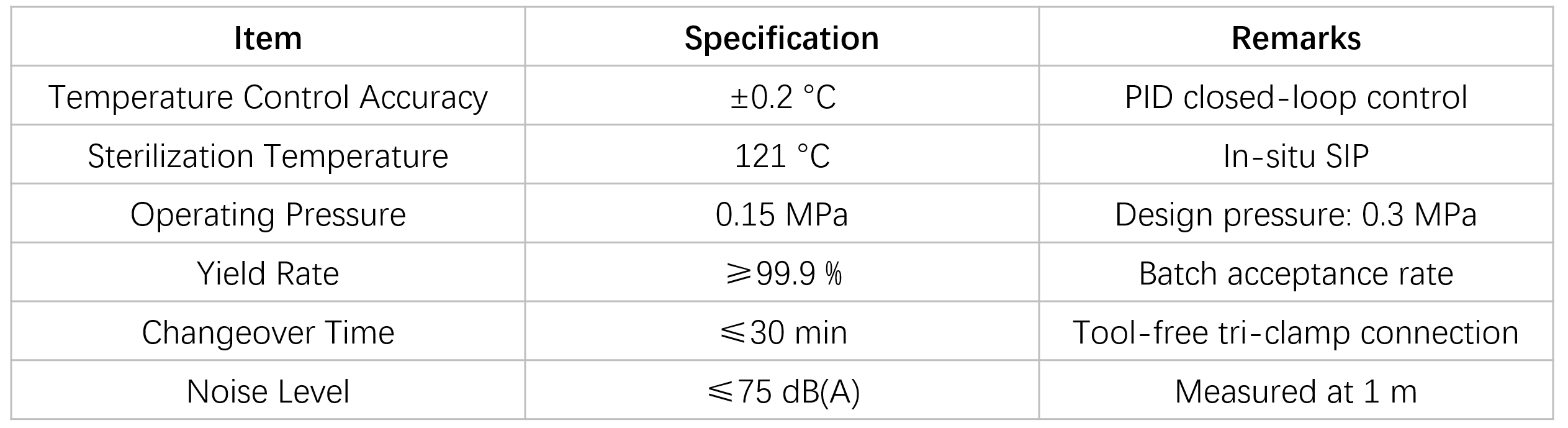

Key Performance Parameters

Construction & GMP Design

316L stainless steel vessel and frame, internal surface finish Ra ≤0.4 μm, external surface Ra ≤0.8 μm, with no hygienic dead zones.

Fully enclosed top cover with tempered glass sight window; all seals made of pharmaceutical-grade EPDM / PTFE.

Quick-connect clamp connection, supporting online CIP/SIP, with a cleaning coverage of ≥99%.

Control System

Siemens S7-1200 / S7-1500 PLC + color touchscreen HMI, ≥50 recipes.

21 CFR Part 11 compliant audit trail and USB/PDF batch record export.

Reserved OPC UA interface for integration with MES / LIMS.

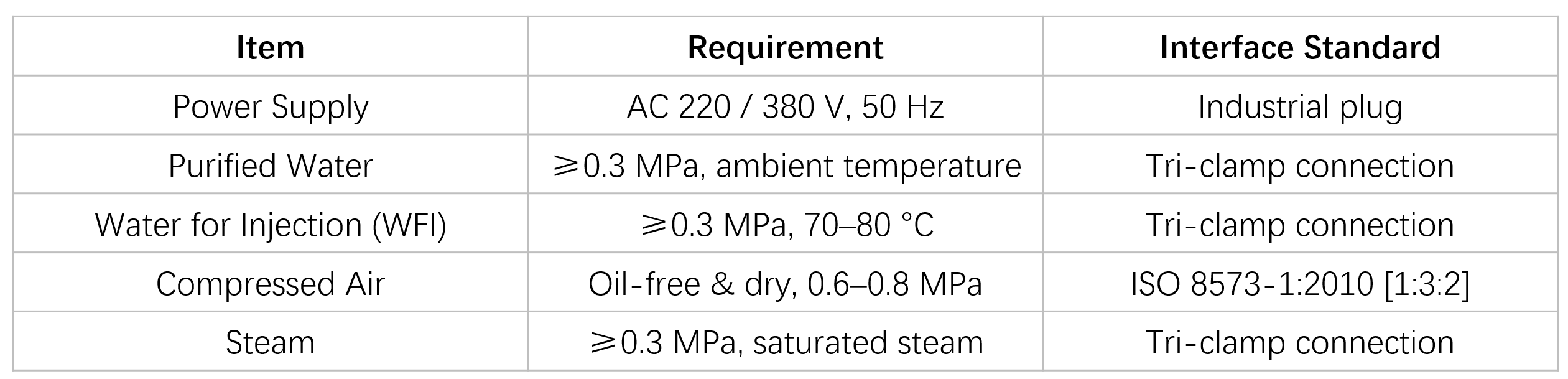

Utility Requirements

BIOTECH-10BS

BIOTECH-100BS

BIOTECH-100JS

GIVE US A MESSAGE