Glass Bottle Syrup Filling Line

BRIEF INTRODUCTION

Product Positioning

Designed to meet GMP-grade production requirements for oral syrup pharmaceutical products, covering the complete process of bottle washing / filling / capping / labeling.

Applicable Packaging Type & Specifications

Packaging Type: Glass bottles for oral liquid products

Fill Volume Range: 20-500 mL

Maximum Output: Up to 12,000 bottles/hour

(verified under 120 mL glass bottles, syrup product conditions)

Process Flow

Bottle infeed → Cleaning (16 blow–suction nozzles, wind speed 0.5-0.6 MPa) →

Filling (accuracy ±1%) → Capping (8/10-head screw capping or roll-on capping, acceptance rate ≥99%) → Labeling (accuracy ±1 mm)

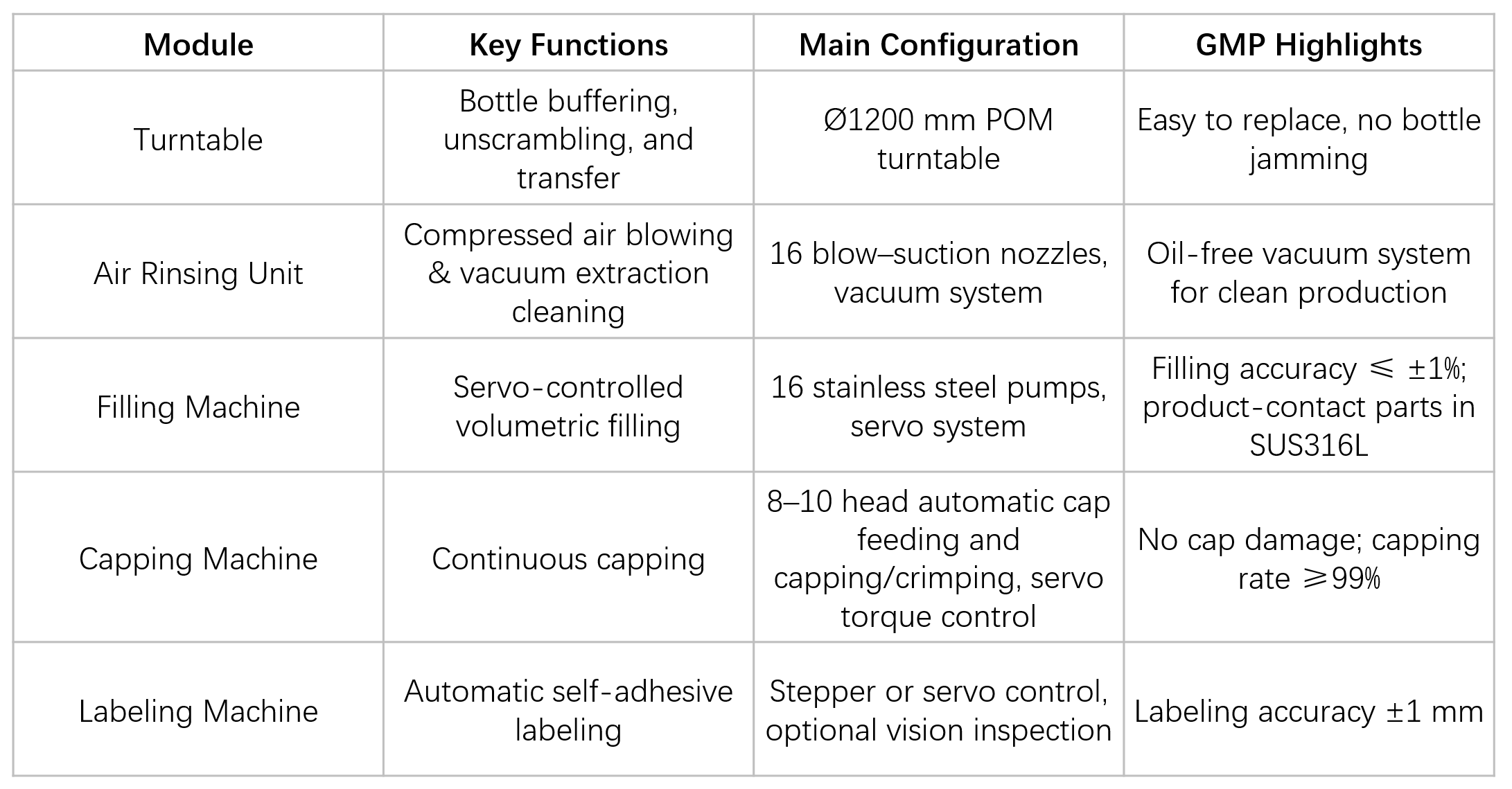

Core Modules

Control System & Data Integrity

Central Control System: The entire line is controlled by a Siemens PLC as the main control unit, enabling synchronized operation of all machines.

Human–Machine Interface (HMI): Touch-screen interface with intuitive operation, supporting Chinese/English language switching.

Servo Control System: Both filling and labeling are driven by servo motors to ensure high-precision performance.

Intelligent Sensor Network: Multiple photoelectric sensors ensure no bottle–no filling / no capping / no labeling, cap-missing alarm, and automatic stop when the line is full.

Data Recording Functions: Supports filling volume statistics, operation log recording, and historical fault/alarm queries.

Cleaning & Sterilization Strategy

Key product-contact parts of the filling system are equipped with CIP (Clean-in-Place), achieving ≥99% cleaning coverage with residue ≤0.1 ppm.

Filter integrity testing is optional.

Applicable scenarios: Pre-sterilized bottles (no dry heat sterilization required on the line); or Non-clean glass bottles requiring water washing and subsequent sterilization off-line.

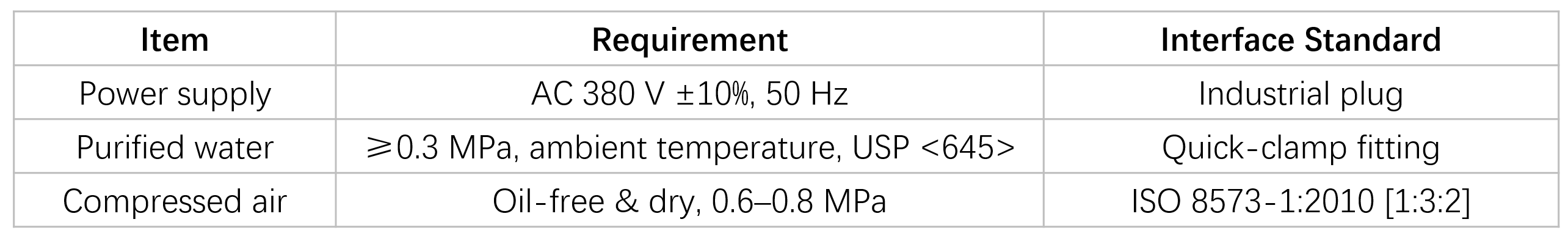

Utility Requirements

JKGP Series Turntable

JQCX Rotary Cylinder Ultrasonic Washing Machine

JKRX Hot Air Circulating Heating and Sterilizing Tunnel

JKGT Filling and Capping Machine

JKLT Vertical Labeling Machine

GIVE US A MESSAGE