Spray Filling and Capping Machine

BRIEF INTRODUCTION

Standalone Machine Positioning

Designed to independently complete filling / spray nozzle insertion / capping operations, meeting GMP requirements for standalone pharmaceutical production.

Applicable Packaging & Specifications

Container type: Plastic bottles (with spray nozzle)

Filling volume range: 10 – 200 mL

Output: 9,000 bottles/hour

(Measured under operating conditions of 10 mL spray bottles filled with aqueous solution)

Process Flow

Bottle unscrambler → Conveyor track transfer → In-machine operations: dual-track servo filling → dual-station spray nozzle insertion → dual-jaw capping → Bottle discharge

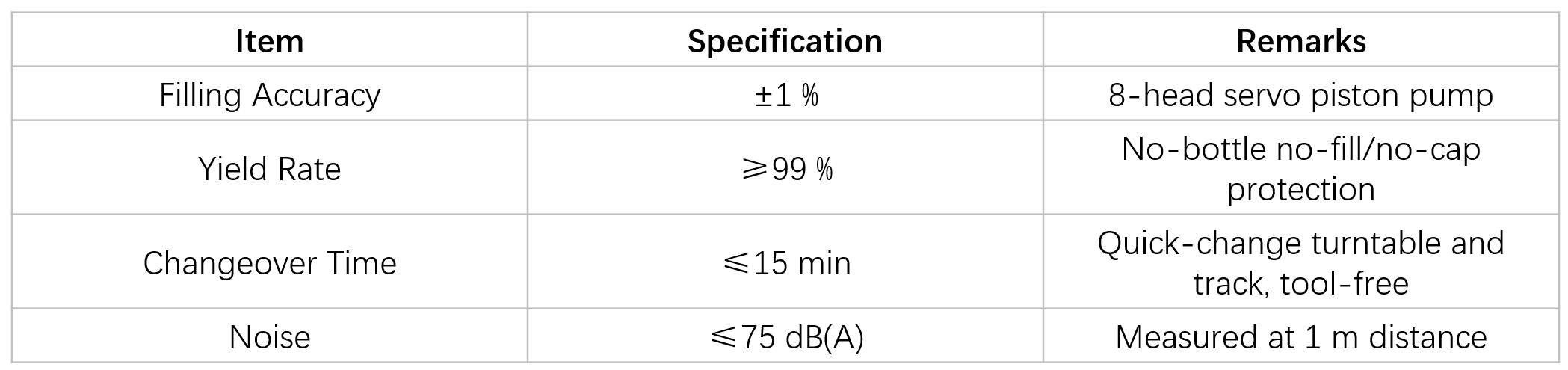

Key Performance Parameters

Structure & GMP Design

All product-contact parts are made of 316L stainless steel, with stainless steel protection on working surfaces; the entire machine complies with GMP standards.

The frame is manufactured from laser-cut single-piece steel plates, featuring a seamless structure with high strength and excellent stability. The tabletop and frame are fully enclosed with 304 stainless steel, ensuring a clean appearance, easy cleaning, and no sharp edges.

Conveyor components use 304 stainless steel bearing housings, Japanese POM engineering plastic modular chains, and 304 stainless steel support plates, ensuring smooth and stable bottle transport.

Filling needles are made of 316L stainless steel. Each needle descends to the bottom of the bottle before filling starts and rises slowly during filling, minimizing downward impact, preventing splashing, and reducing excessive foaming.

Control System

Equipped with a Siemens touchscreen HMI, three-level password-based access control, and PLC control, providing intuitive operation and real-time process visualization.

The main motor is from ABB (Switzerland), while the PLC, frequency inverter, and servo drives are all Siemens (Germany) components, ensuring high reliability.

Equipped with no-bottle–no-filling and no-bottle–no-capping functions, automatic stop in case of no bottle, as well as output counting and alarm display, ensuring a high level of automation.

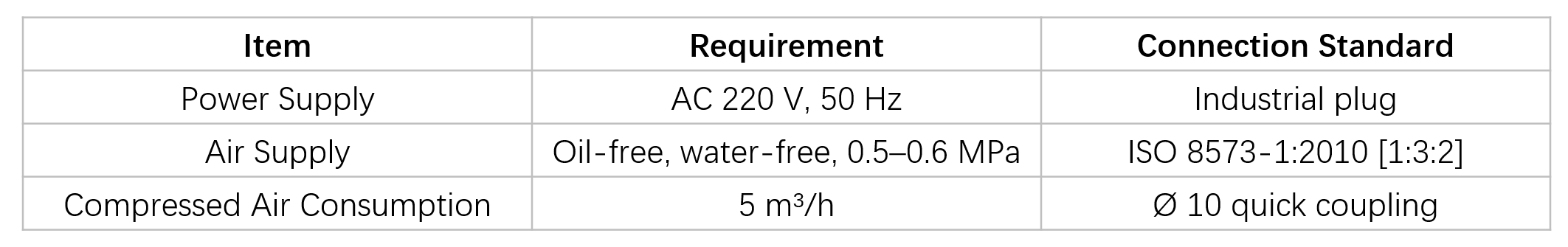

Utility Requirements

GIVE US A MESSAGE