XWZ300 II Intelligent High Speed Cartoner

BRIEF INTRODUCTION

Standalone Machine Positioning

Independently performs automatic carton suction, carton opening, leaflet folding, cartoning, batch coding, carton sealing, and reject functions, meeting GMP requirements for standalone production.

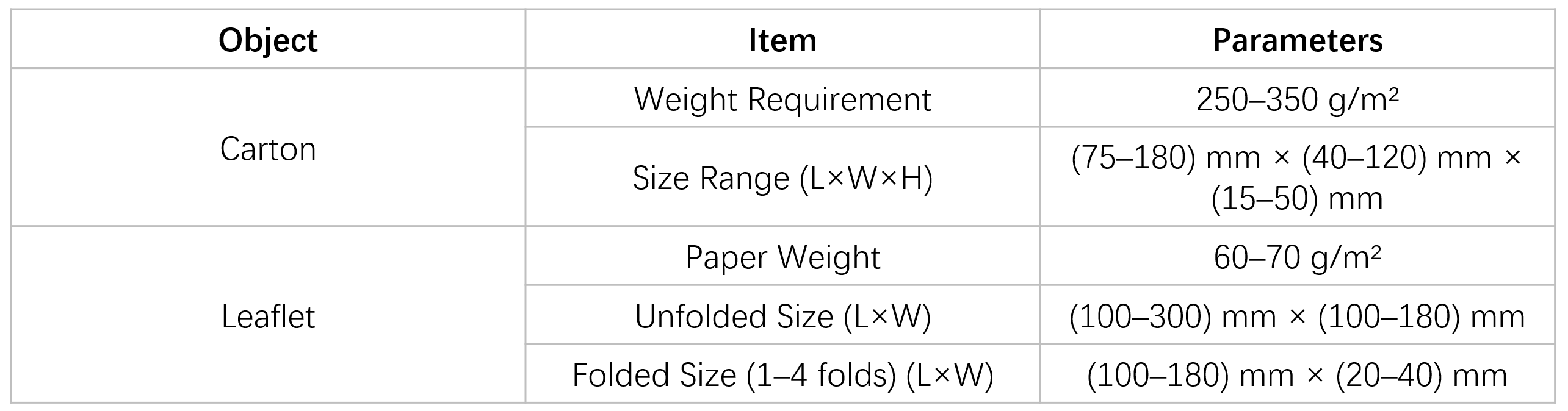

Applicable Packaging Types & Specifications

Applicable products:

Blister packs

Vials

Ampoules

Ointment tubes

Injection trays

Rectangular products

Flat products

Production capacity: 60 – 220 cartons/min

Process Flow

Manual / automatic feeding → Machine process: automatic carton suction → carton opening → product loading → leaflet insertion → batch coding → carton sealing → rejection → Carton discharge

Key Technical Parameters

Structure and GMP Design

The labeling machine head adopts a three-section design, consisting of the label supply, label pulling, and backing paper recovery mechanisms, each driven by an independent motor to ensure fast and stable label transport.

A rotary table feeding system is used, offering high adaptability and easy cleaning, and supports both manual feeding and inline operation.

An optional differential bottle feeding mechanism is available, which can adapt to different bottle specifications by simply adjusting the mechanism position without changing parts. A screw-type bottle feeding mechanism is also available as an alternative.

The wheel-mounted belt uses a synchronous belt, and the pressure plate is equipped with cushioning sponge, ensuring smooth operation, good buffering, strong label adhesion, and preventing bottle breakage.

Control System

The machine is equipped with a touchscreen HMI, which automatically displays faults and guides troubleshooting in case of abnormalities, making operation simple and user-friendly.

It features recipe selection and storage, allowing operators to switch product specifications without resetting parameters by simply calling the stored recipe, thereby improving work efficiency.

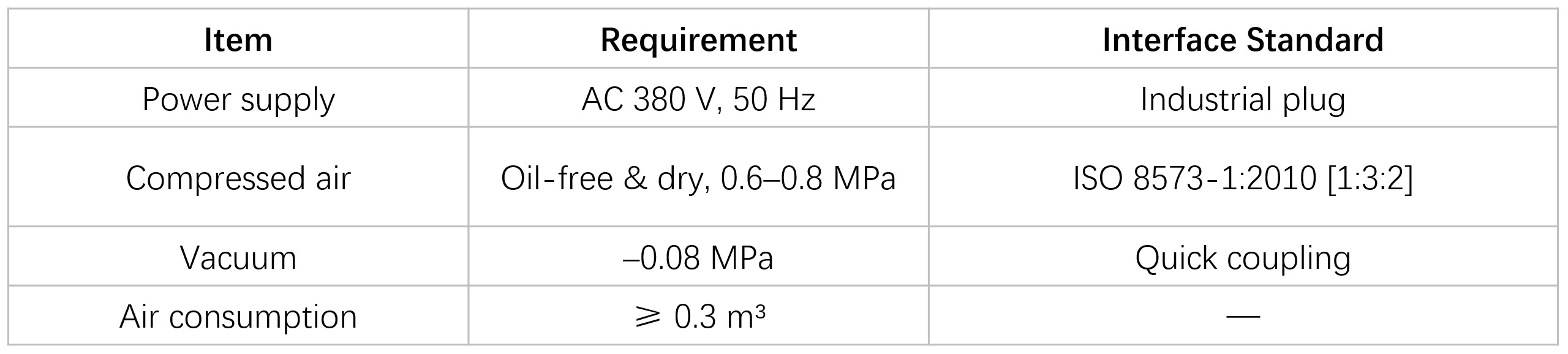

Utility Requirements

GIVE US A MESSAGE