Non-PVC Film Soft Bag Filling Line

BRIEF INTRODUCTION

Product Positioning

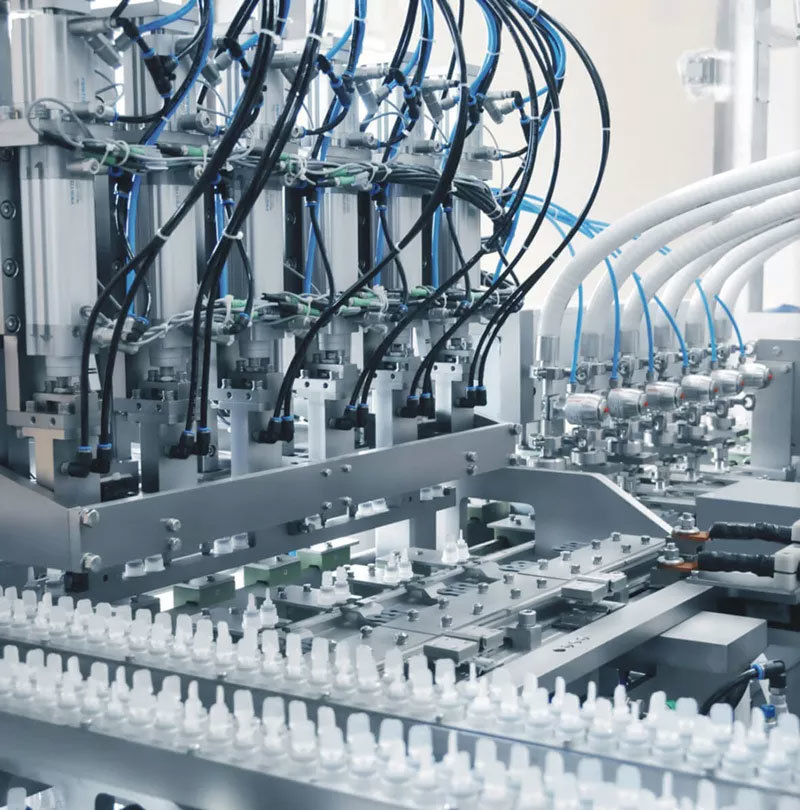

Designed to meet GMP-compliant, fully automated production requirements for aseptic large-volume parenterals (LVP), covering the complete process from film roll feeding → bag forming → filling → sealing → bag discharge.

Applicable Packaging & Specifications

Packaging type: Non-PVC multilayer film bags

Volume range: 50 – 2,000 mL

Peak capacity: 600 bags/hour

(tested with 500 mL bags containing aqueous solution)

Process Flow

Material feeding → Machine operations: thermal transfer printing → bag forming → port welding → filling (accuracy ±0.5%) → sealing (non-contact, dust-free) → Bag discharge

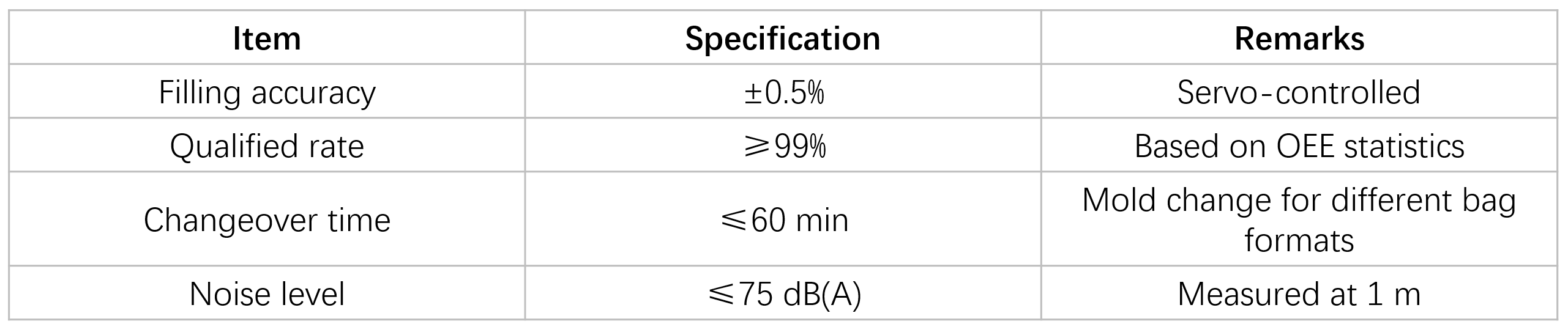

Key Performance Parameters

Control System & Data Integrity

Siemens PLC + industrial touchscreen; supports 21 CFR Part 11 audit trail.

Recipe management, ≥100 sets, one-click switching.

Batch record generation, electronic signature, PDF export, MES integration (via OPC UA).

Cleaning / Sterilization Strategy

Fully automatic CIP/SIP, filling system sterilized online at 121 °C without component replacement; residual removal complete.

Cleaning coverage ≥99%, no residual liquid; all connecting parts made of 316L stainless steel, corrosion-resistant and high-temperature resistant.

Non-toxic hoses and gaskets, withstand up to 125 °C without particle shedding.

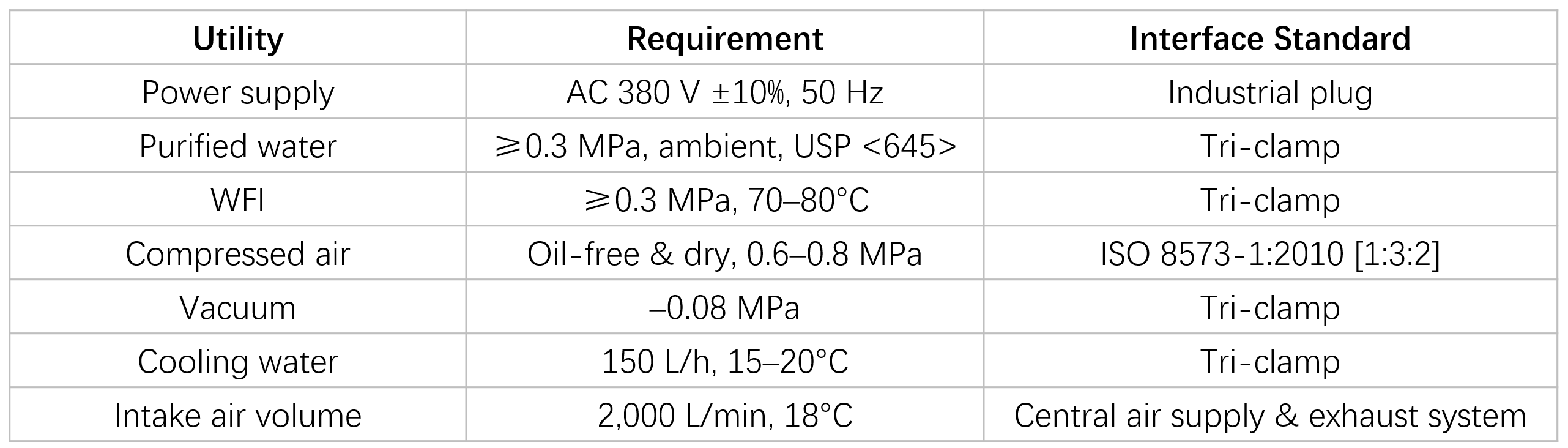

Utilities Requirements

GIVE US A MESSAGE