Eye Drop Filling Line

BRIEF INTRODUCTION

Product Positioning

Designed to meet GMP-compliant production requirements for pharmaceuticals such as sterile preparations, covering the entire process of bottle unscrambling / filling / stoppering / capping / laminar airflow protection.

Applicable Packaging Type & Specifications

Container type: Eye drop bottles

Filling volume range: 5 – 30 mL

Maximum output: 7,200 bottles/hour

(Measured under operating conditions of 5 mL ophthalmic solution bottles filled with aqueous solution)

Process Flow

Bottle infeed → Filling: accuracy ±0.5 – 1%, ceramic piston pump → Stoppering: accuracy ≥ 99%, fiber optic detection and control → Capping: constant torque control, qualified rate ≥ 99.8% → Laminar airflow hood (local Class 100 / ISO 5, with glove ports)

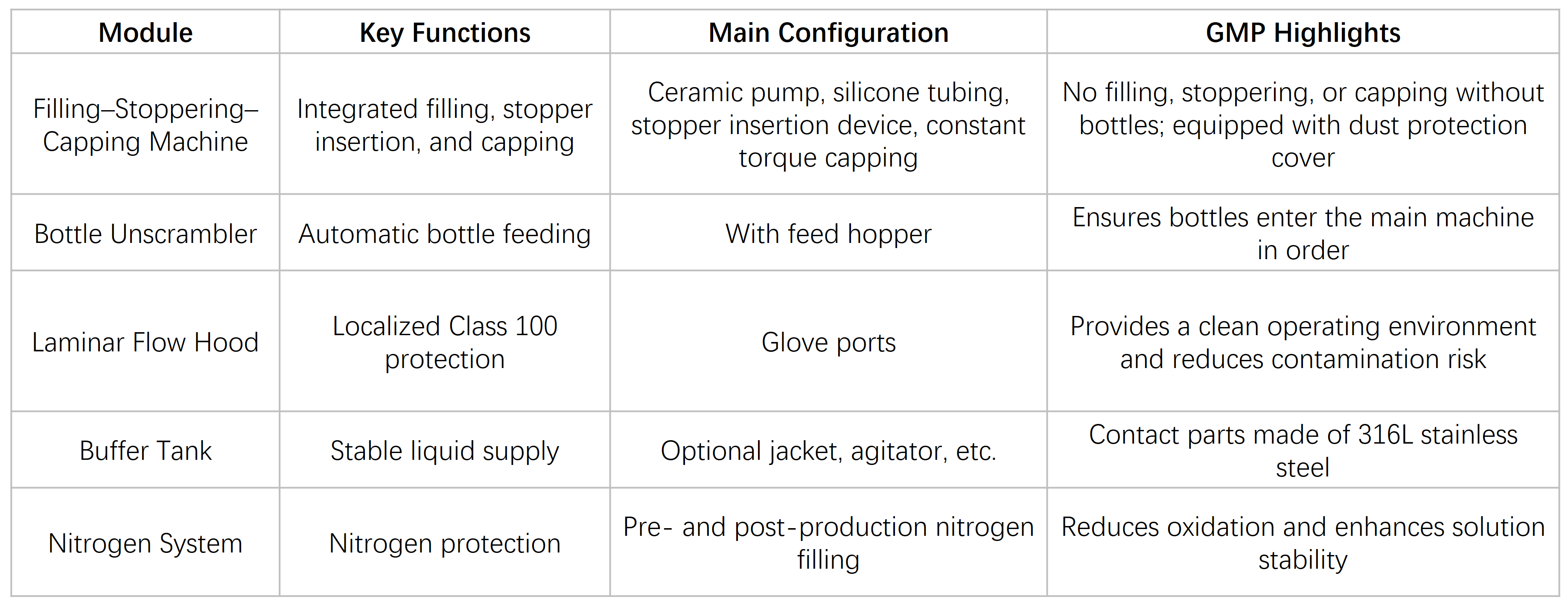

Core Modules

Control System & Data Integrity

Equipped with Siemens PLC and HMI touchscreen.

Supports recipe storage and rapid changeover.

Backup available for both PLC and HMI programs.

Cleaning & Sterilization Strategy

Fully automatic CIP/SIP with cleaning coverage ≥ 99% and residue ≤ 0.1 ppm.

Filter integrity testing: online PALL integrity tester with automatic report printing.

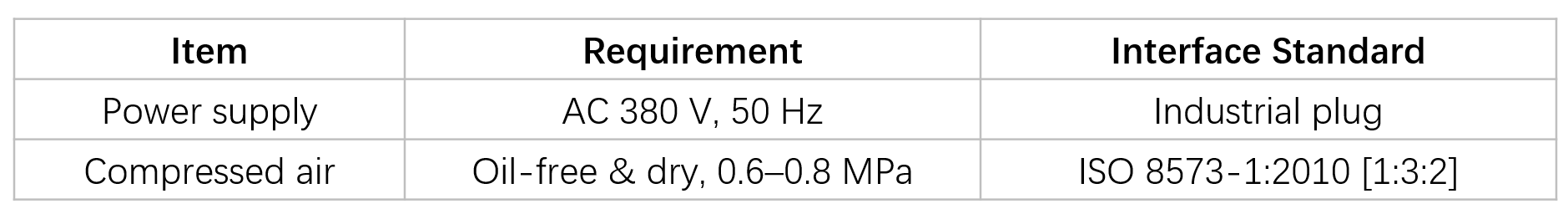

Utility Requirements

GIVE US A MESSAGE