DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

BRIEF INTRODUCTION

Standalone Positioning

Independently completes forming, filling, heat sealing, cutting, and batch number embossing processes, fully meeting GMP requirements for standalone production.

Applicable Packaging & Specifications

Packaging Types: Aluminum / PVC blister boards, Aluminum / Aluminum (PTP) blister boards

Punching Speed: 20–40 cycles/min (Al/Al), 20–50 cycles/min (Al/PVC)

Feeding Stroke Optional Range: 30–120 mm

Maximum Forming Area: 160 × 112 mm²

Maximum Forming Depth: 12 mm (Al/Al), 18 mm (Al/PVC)

Standard Plate: 80 × 57 × 2 mm

Process Flow

Manual / Automatic Loading → [Integrated Processes of This Unit: Positive Pressure Forming → Servo Feeding → Heat Sealing → Batch Number Embossing → Punching → Scrap Edge Winding] → Qualified Blister Board Discharge

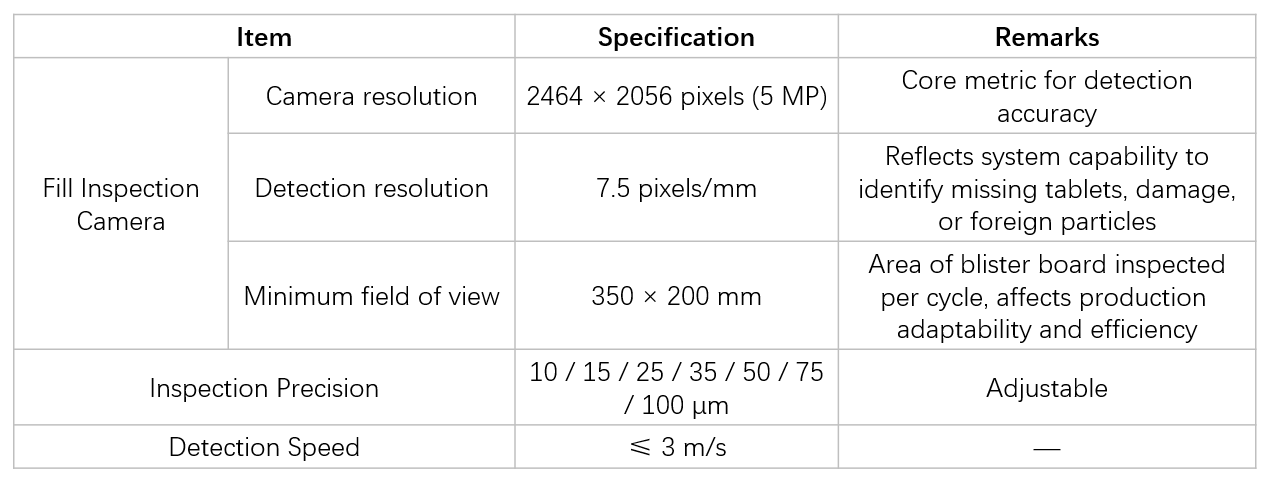

Key Performance Parameters

Structure & GMP Design

Modular Construction: Machine can be disassembled for elevator transport and modular cleanroom installation; reassembly uses screws + cylindrical pins for fast alignment and convenient installation.

Stable Forming & Heat Sealing: Automatic closing heating plates, air cushion heat sealing, and interlocking male-female mesh structures reduce material waste, prevent thermal deformation during downtime, improve sealing quality, and extend machine life.

Precise Drive & Feeding System: Variable frequency main motor, robotic feeding clamp, adjustable stroke 30–120 mm, smooth and accurate operation, suitable for multi-spec production.

Intelligent & GMP Compliance: PVC sheet breakage alarm, electronic counting, integrated batch embossing and punching workflow; all product-contact parts are stainless steel or non-toxic material, fully compliant with GMP.

Control System

Siemens PLC + color touchscreen, 100 formula sets, one-key switching.

Three-level password protection, 21 CFR Part 11 compatible: electronic signatures, automatic batch record generation, USB/PDF export.

Reserved RS-485 / Ethernet interface, supports OPC UA, can connect directly to MES.

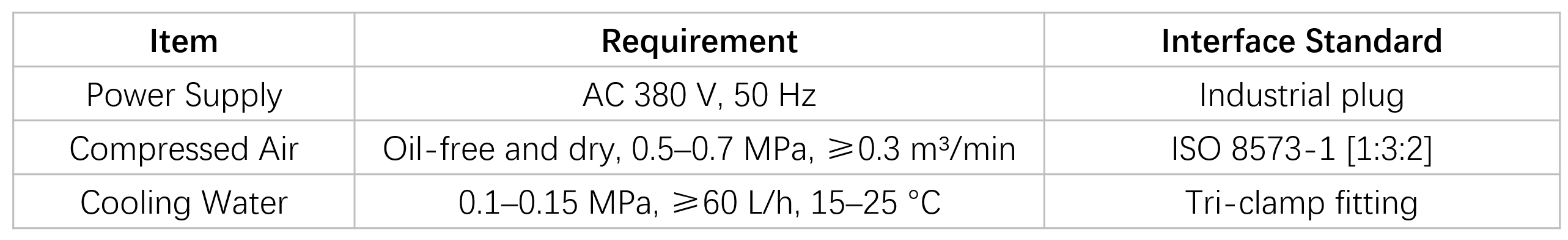

Utility Requirements

Dimensions

GIVE US A MESSAGE