Water Distiller

BRIEF INTRODUCTION

Standalone Positioning

Independently completes the Water for Injection (WFI) generation process, meeting GMP requirements for standalone operation.

Application Scope & Capacity

Application: Water for Injection (WFI)

Capacity Range: 100 – 10,000 L/h

(Measured under industrial steam conditions of 6–8 bar)

Process Flow

Manual / Make-up Water → Integrated Process of This Unit: Falling Film Flash Evaporation → 180° Vapor–Liquid Gravity Separation → Centrifugal Spiral Separation → Continuous Non-Condensable Gas Removal → WFI Outlet

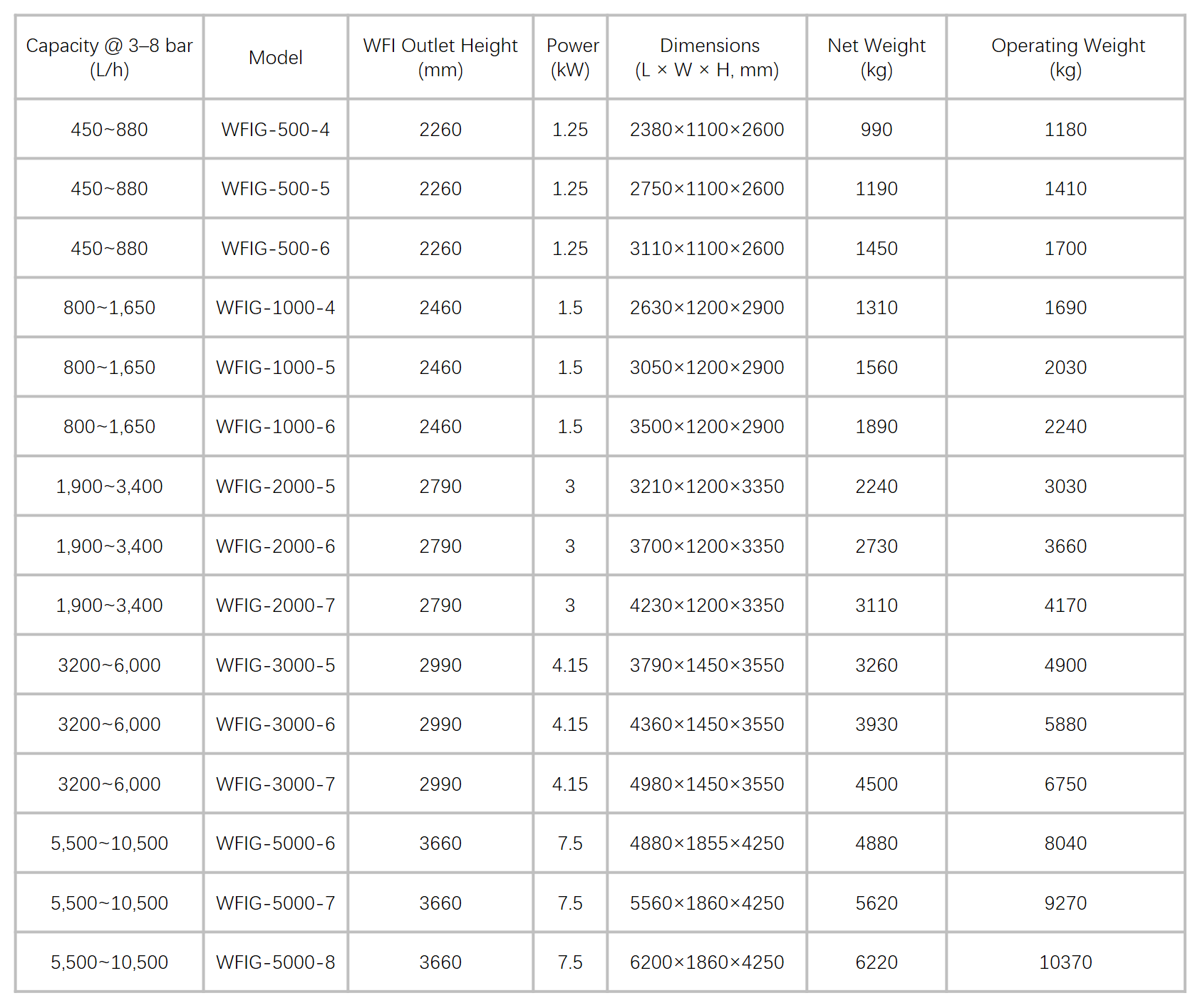

Product Models & Technical Parameters

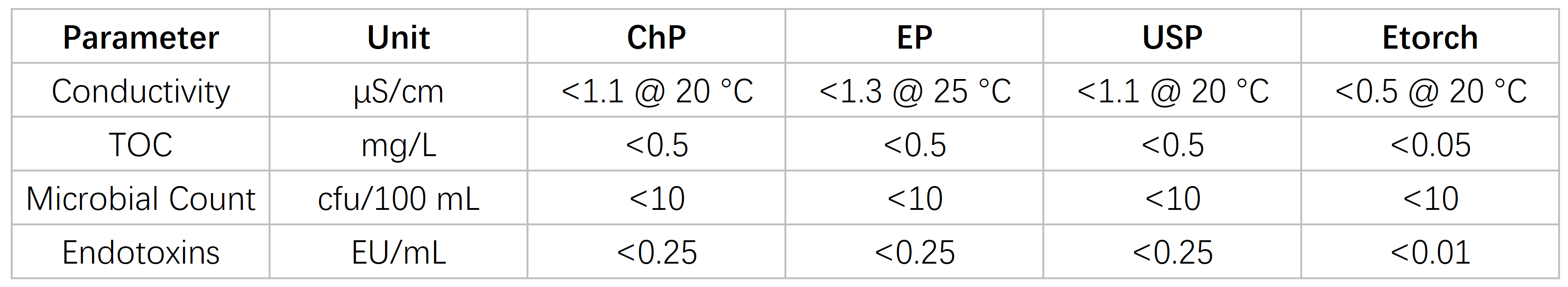

Complied Pharmacopoeia Standards

Control System

Siemens S7-1500 PLC + 12" color HMI, ≥100 recipes

21 CFR Part 11 compliant: three-level access control, audit trail, electronic signature

Data export: USB / PDF batch records + OPC UA interface, ready for MES / LIMS integration

Remote diagnostics: VPN encrypted access with 24-hour manufacturer support

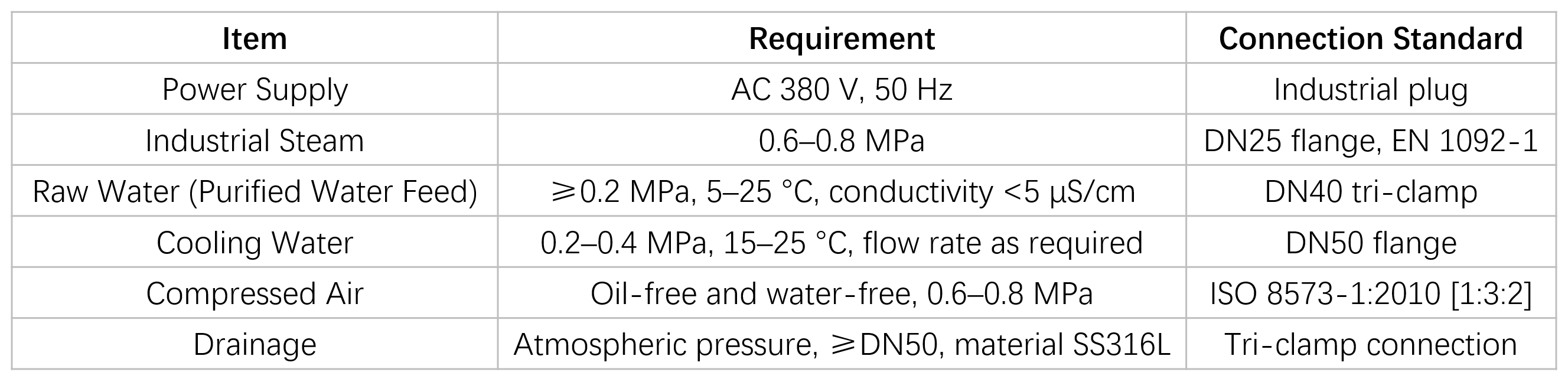

Utility Requirements

S series multi-effect water distiller

F Series Multi-Effect Water Distiller

B Series Multi-Effect Water Distiller

GIVE US A MESSAGE