DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

BRIEF INTRODUCTION

Standalone Machine Positioning

Independently completes the blister packaging process, meeting GMP requirements for standalone production.

Applicable Packaging Types & Specifications

Packaging formats:

Alu / Plastic (PVC) blister packs

Alu / Alu (PTP) blister packs

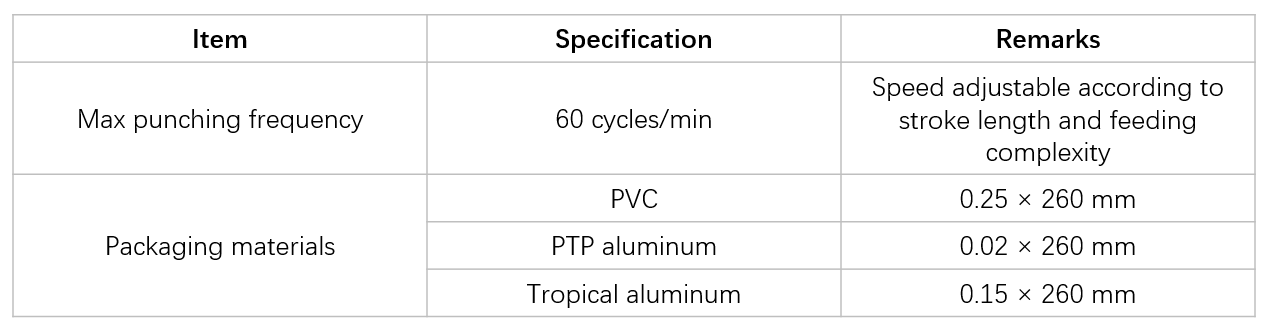

Punching speed:

20–40 cycles/min (Alu–Alu)

20–60 cycles/min (Alu–PVC)

Feed stroke range: 30–120 mm

Max forming area: 260 × 115 mm²

Max forming depth:

12 mm (Alu–Alu)

18 mm (Alu–PVC)

Standard blister size: 80 × 57 × 4 mm

Process Flow

Manual / automatic feeding → Machine process: forming → special automatic feeding → sealing → punching → embossing → blister cutting → Discharge

Key Performance Parameters

Structure & GMP Design

Multi-function & Quick Mold Change: Supports both Alu–Alu and Alu–PVC packaging. The machine can be transported in separate sections and rapidly assembled using positioning pins and bolts. Mold plates are clamped, and forming and heat-sealing molds require no parallel or lateral adjustments, enabling true quick mold change.

Material-saving & Discharge: Waste-free lateral punching design significantly reduces material costs. After punching, products are discharged with the assistance of ejector pins to ensure smooth output and eliminate safety hazards. An extended worktable improves operational flow.

High-precision Dosing & Multi-type Feeders: Equipped with dual combination feeders achieving filling rates above 99%. Supports various specialized feeders (rotary vibration, push-plate, sieving, capsule feeding, etc.) to accommodate different dosage forms in Alu–PVC packaging, reducing missing tablets, mis-shaped tablets, and underfilled cavities.

Clean, Safe & Visible Operation: Stainless steel drive and operator zones are fully enclosed with sheet metal to prevent cross-contamination. Batch numbers are printed with heat marking, providing clear legibility. Transparent protective covers allow visual monitoring and enhance safety. The equipment operates quietly and smoothly, with no abnormal thermal deformation, and features emergency stop protection and full-process automatic monitoring with alarms.

Control System

Siemens PLC + touchscreen control

Functions include electronic counting, batch coding, perforation cutting line control, punching, and automatic stop with alarm in case of incomplete blister cutting

Emergency stop safety devices enhance operator safety during adjustment and mold changeover

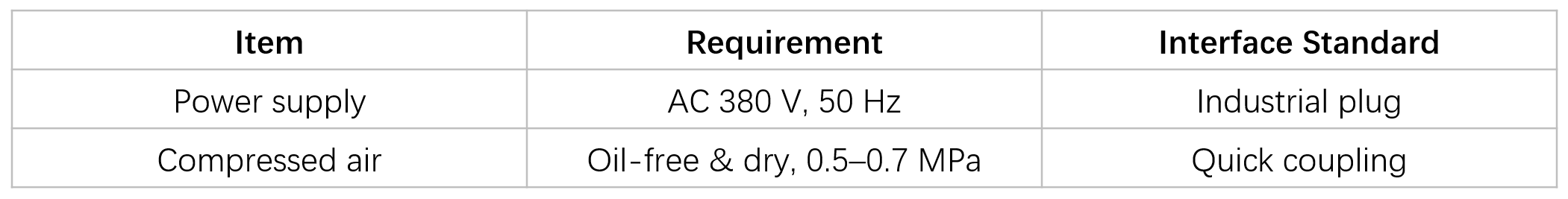

Utility Requirements

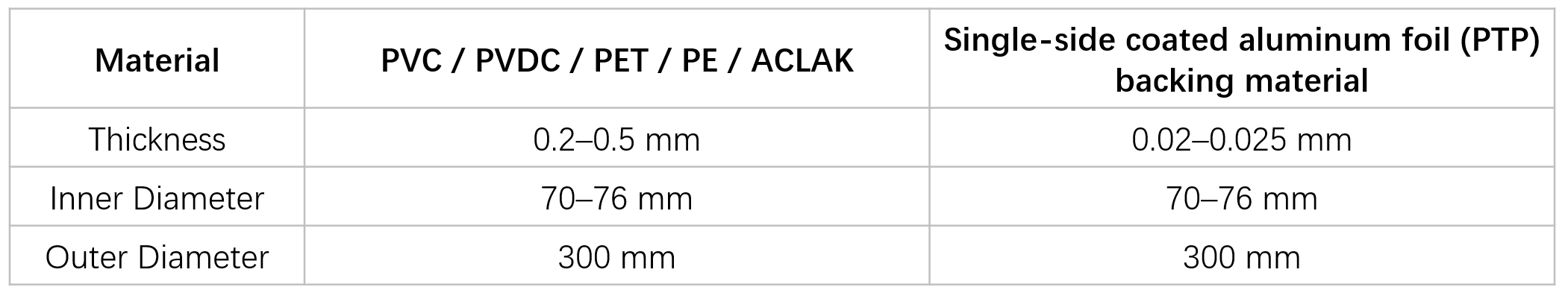

Roll-type Packaging Materials

Dimensions

GIVE US A MESSAGE