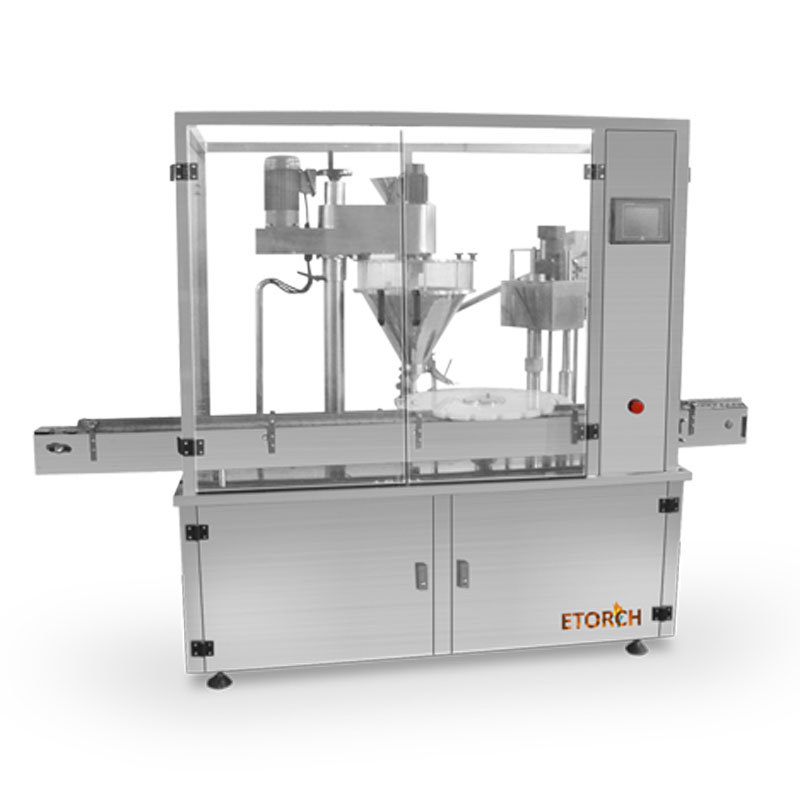

Powder Filling and Capping Machine

JKFZ Powder Filling and Capping Machine is a specialized unit designed for the efficient filling and capping of powder and solid particle products. This machine is suitable for use in the pharmaceutical and food industries, ensuring high productivity and accuracy in packaging.

Sterile Powder Filling Machine

Sterile powder filling machine is a new generation of ultra-high speed screw dividing machine developed by our engineering and technical staff.

Pure water equipment requirements:The water quality meets all the provisions of China pharmacopoeia standard and FDA; Automatic equipment operation and conditional automatic processing program (such as back flush, regeneration, acid-washing and disinfection procedures); Monomer and pipe equipment meet GMP requirements (all such back end processing equipments as sterilizer, membrane filtration, terminal water tank and pipeline adopt the 316L material and the pre-treatment pipeline adopts SUS304 material).

S series multi-effect water distiller is designed according to the principle of falling film and multiple-stage evaporation. The first effect is to conduct heating by external heat source (industrial steam), and then each pillar can get enough heat energy by using the pure vapor produced from the fore-effect. The material water that did not evaporate in the first effect can be taken as the material in the next effect, and so on.

The standard equipment model table shows the production capacity of the units at 3 bar pure steam pressure and 6 bar industrial steam pressure, expressed in kg/h. For certain equipment types, the actual production capacity should be calculated based on the actual operating pressure and multiplied by the specified capacity conversion factor. Regarding utility requirements, the industrial saturated steam must be free of impurities and corrosive substances, with a maximum allowable pressure of 9 bar. The feed water must be deionized water, free from silica, chlorine, amines, and volatile substances, with a required pressure of 1–2 bar. The power supply standard shall be provided according to customer requirements. Compressed air must be dry, oil-free, and clean, with a minimum required pressure of 6 bar.

The Preparation System is designed for material preparation in industries such as bioengineering, large infusions, oral solutions, and fine chemistry. It effectively mitigates the risks of cross-contamination and product contamination during the preparation process, enhancing production efficiency and product reliability.

The fermentation system includes seed tanks, fermenters, control systems, air handling systems, feeding systems, piping systems, valves, operating platforms, and utilities. We also manufacture downstream processing systems for our clients. Based on user requirements, we can design complete fermentation workshops and are responsible for on-site installation and commissioning. Our company additionally provides employee training and supplies GMP documentation to assist users.

Automatic counting machine is specifically designed for counting tablets, soft gelatin capsules, hard capsules, and pills.

Light Inspection and Leakage Detection Machine

This inspection machine is designed to detect leaks and inspect vials, ampoules, lyophilized products, flexible bags, and BFS ampoules.

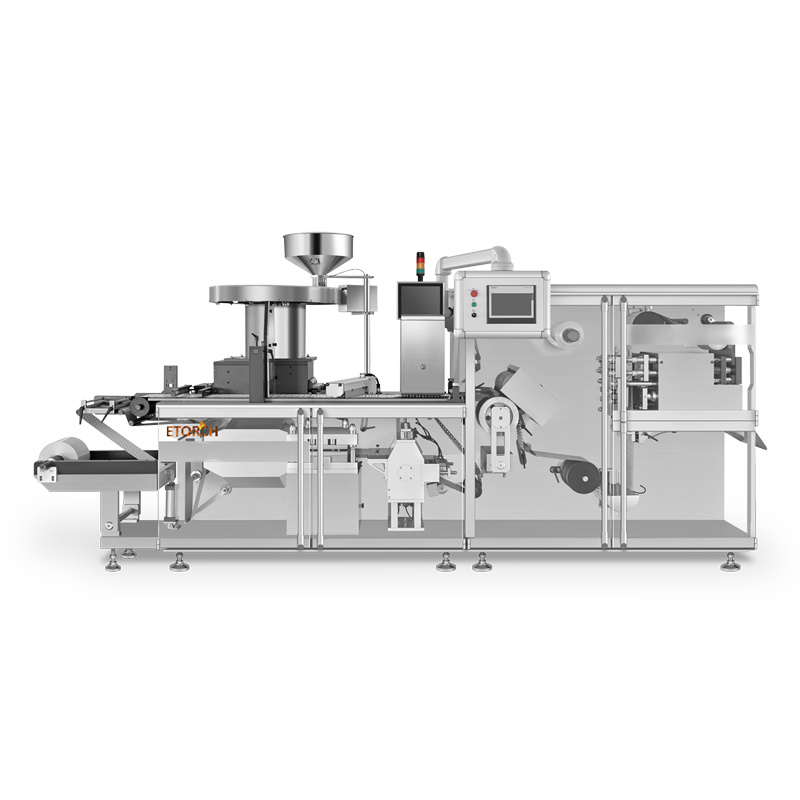

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP160F is a blister machine in the intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

The DPP260TI Intelligent Flat-Plate Alu-Plastic / Alu-Alu Blister Packaging Machine is a specialized piece of equipment designed for blister composite sealing packaging of pharmaceuticals (tablets, capsules, ampoules), food products, medical devices, and similar materials, using aluminum/plastic or aluminum/aluminum (PTP) formats. By adopting positive-pressure forming and flat-plate heat sealing, the machine produces blisters with well-defined shape and rigidity and smooth, even blister cards, making it highly favored by professionals across the industry.

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

The DPH260H Intelligent High-Speed Roller-Plate Alu-Plastic / Alu-Alu Blister Packaging Machine (granted a National Invention Patent, Patent No. ZL 201010213970.1) is a specialized machine for blister composite sealing packaging of pharmaceuticals (tablets and capsules), food products, medical devices, health supplements, electronic components, and similar items, using aluminum (PTP) / plastic (PVC) materials. By adopting positive-pressure forming and roller-type heat sealing, the machine produces well-defined, rigid blisters and flat, uniform blister cards, ensuring high packaging quality and reliability.

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

Powder Filling and Capping Machine

JKFZ Powder Filling and Capping Machine is a specialized unit designed for the efficient filling and capping of powder and solid particle products. This machine is suitable for use in the pharmaceutical and food industries, ensuring high productivity and accuracy in packaging.

Sterile Powder Filling Machine

Sterile powder filling machine is a new generation of ultra-high speed screw dividing machine developed by our engineering and technical staff.

Pure water equipment requirements:The water quality meets all the provisions of China pharmacopoeia standard and FDA; Automatic equipment operation and conditional automatic processing program (such as back flush, regeneration, acid-washing and disinfection procedures); Monomer and pipe equipment meet GMP requirements (all such back end processing equipments as sterilizer, membrane filtration, terminal water tank and pipeline adopt the 316L material and the pre-treatment pipeline adopts SUS304 material).

S series multi-effect water distiller is designed according to the principle of falling film and multiple-stage evaporation. The first effect is to conduct heating by external heat source (industrial steam), and then each pillar can get enough heat energy by using the pure vapor produced from the fore-effect. The material water that did not evaporate in the first effect can be taken as the material in the next effect, and so on.

The standard equipment model table shows the production capacity of the units at 3 bar pure steam pressure and 6 bar industrial steam pressure, expressed in kg/h. For certain equipment types, the actual production capacity should be calculated based on the actual operating pressure and multiplied by the specified capacity conversion factor. Regarding utility requirements, the industrial saturated steam must be free of impurities and corrosive substances, with a maximum allowable pressure of 9 bar. The feed water must be deionized water, free from silica, chlorine, amines, and volatile substances, with a required pressure of 1–2 bar. The power supply standard shall be provided according to customer requirements. Compressed air must be dry, oil-free, and clean, with a minimum required pressure of 6 bar.

The Preparation System is designed for material preparation in industries such as bioengineering, large infusions, oral solutions, and fine chemistry. It effectively mitigates the risks of cross-contamination and product contamination during the preparation process, enhancing production efficiency and product reliability.

The fermentation system includes seed tanks, fermenters, control systems, air handling systems, feeding systems, piping systems, valves, operating platforms, and utilities. We also manufacture downstream processing systems for our clients. Based on user requirements, we can design complete fermentation workshops and are responsible for on-site installation and commissioning. Our company additionally provides employee training and supplies GMP documentation to assist users.

Automatic counting machine is specifically designed for counting tablets, soft gelatin capsules, hard capsules, and pills.

Light Inspection and Leakage Detection Machine

This inspection machine is designed to detect leaks and inspect vials, ampoules, lyophilized products, flexible bags, and BFS ampoules.

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP160F is a blister machine in the intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

DPP160F Intelligent Plate ALU/PVC and ALU/ALU Blister Packing Machine

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

The DPP260TI Intelligent Flat-Plate Alu-Plastic / Alu-Alu Blister Packaging Machine is a specialized piece of equipment designed for blister composite sealing packaging of pharmaceuticals (tablets, capsules, ampoules), food products, medical devices, and similar materials, using aluminum/plastic or aluminum/aluminum (PTP) formats. By adopting positive-pressure forming and flat-plate heat sealing, the machine produces blisters with well-defined shape and rigidity and smooth, even blister cards, making it highly favored by professionals across the industry.

DPP260TI Intelligent Plate ALU/PVC and ALU/ALU Blister Machine

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine

The DPH260H Intelligent High-Speed Roller-Plate Alu-Plastic / Alu-Alu Blister Packaging Machine (granted a National Invention Patent, Patent No. ZL 201010213970.1) is a specialized machine for blister composite sealing packaging of pharmaceuticals (tablets and capsules), food products, medical devices, health supplements, electronic components, and similar items, using aluminum (PTP) / plastic (PVC) materials. By adopting positive-pressure forming and roller-type heat sealing, the machine produces well-defined, rigid blisters and flat, uniform blister cards, ensuring high packaging quality and reliability.

DPH260H Intelligent High Speed Roller-Plate ALU/PVC and ALU/ALU Blister Packing Machine